Introduction: Understanding the Critical Link Between Materials and Safety

When it comes to hammock safety, few factors matter more than the relationship between the material and its weight capacity. This connection isn’t just about comfort—it’s fundamentally about preventing accidents and ensuring your relaxation doesn’t turn into an emergency.

Every hammock has its limits, and exceeding these can lead to sudden failures that result in injuries. Understanding what makes one hammock capable of supporting 200 pounds while another safely cradles 500 pounds empowers you to make informed decisions that prioritize both comfort and safety.

The weight capacity of a hammock depends on several interconnected elements:

– The primary material (nylon, cotton, polyester, etc.)

– Material specifications (thickness, weave pattern)

– Construction quality (stitching, suspension points)

– Support hardware strength

By the end of this guide, you’ll understand how each element contributes to a hammock’s overall strength and be equipped to select a product that meets your specific needs while prioritizing safety. Comprehensive hammock weight capacity guidelines serve as the foundation for making smart purchasing decisions that will provide years of safe enjoyment.

Before diving into specific materials, it’s important to understand that proper hammock weight support involves more than just fabric strength—it’s an integrated system where each component must work together.

The Science Behind Hammock Weight Ratings

Weight capacity ratings aren’t arbitrary numbers—they’re derived from engineering principles and testing methods that ensure your safety. Understanding what these ratings really mean can help you make better decisions when selecting your perfect hammock.

Static vs. Dynamic Loads: A hammock’s weight capacity typically refers to its static load capacity—the weight it can support when you’re lying still. Dynamic loads occur when you sit down quickly, shift positions, or swing, creating momentary forces that can be 1.5-2 times your actual weight. This is why manufacturers build in safety margins.

When engineers design hammocks, they incorporate safety factors into their weight ratings. Most quality hammocks are designed to handle loads 25-50% higher than their stated capacity before reaching a critical failure point. However, regularly exceeding the rated capacity accelerates wear and can lead to premature failure.

Weight capacity represents the culmination of multiple factors working in harmony:

– The material’s inherent tensile strength

– The quality and pattern of stitching

– The suspension system’s integrity

– Hardware component strength ratings

Understanding how much weight a hammock can hold involves recognizing that failure typically happens at the weakest link in this chain. For some hammocks, that’s the fabric itself; for others, it might be the suspension straps or attachment points. The most catastrophic failures often occur at connection points where stress concentrates.

Primary Hammock Materials: Strength Properties Compared

Nylon (Including Ripstop and Parachute Varieties)

Nylon has become one of the most popular hammock materials due to its exceptional strength-to-weight ratio. This synthetic material offers impressive tensile strength while remaining lightweight and packable.

The denier rating (D) directly indicates the thickness of the fibers used—higher numbers mean stronger, heavier fabric. For hammocks:

– 40D: Ultralight backpacking hammocks (typically 250-300 lb capacity)

– 70D: Standard recreational hammocks (300-400 lb capacity)

– 210D: Heavy-duty camping hammocks (400-500+ lb capacity)

Nylon’s natural elasticity provides a comfortable cradle effect and helps absorb dynamic forces when entering or moving in the hammock. This stretch characteristic actually contributes to safety by distributing weight more evenly across the fabric.

Ripstop nylon, with its reinforcement threads woven in a grid pattern, offers superior tear resistance. Even if a small puncture occurs, the ripstop construction prevents it from spreading, maintaining the hammock’s structural integrity.

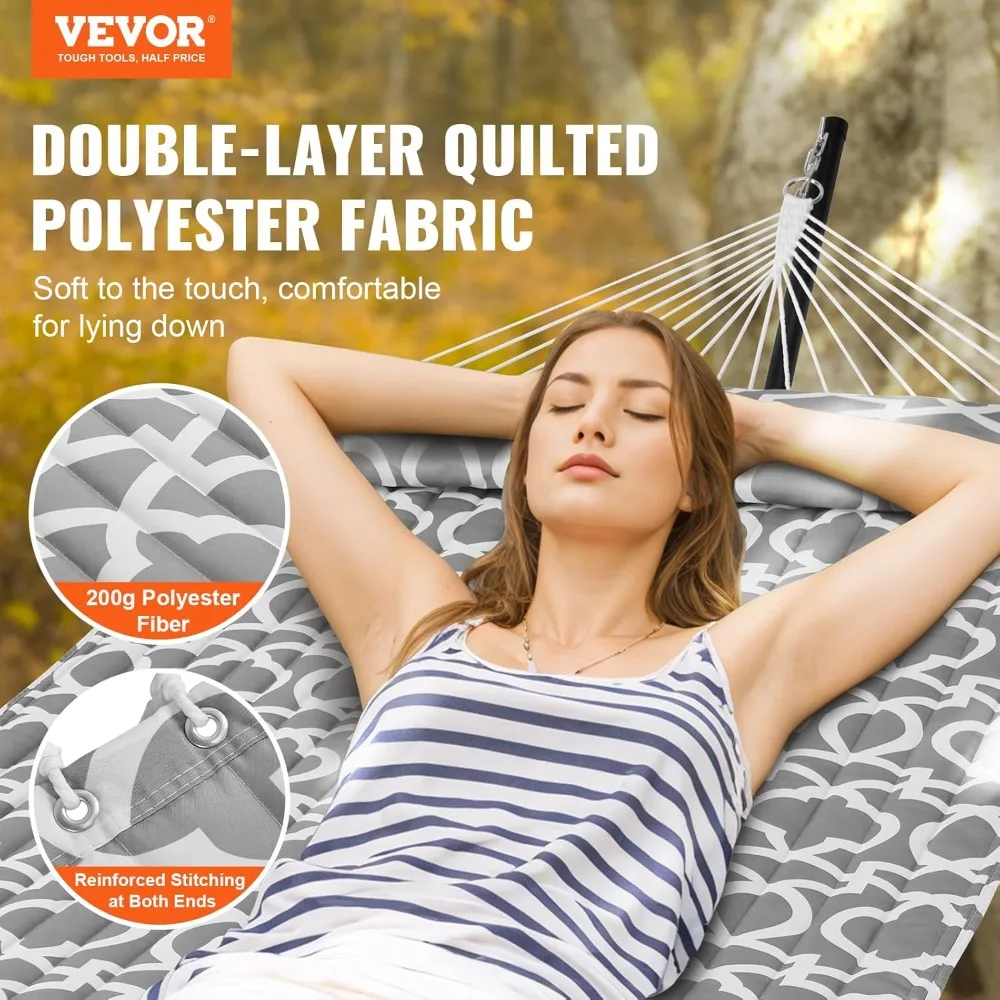

Polyester

Polyester offers distinct advantages over nylon in certain conditions, particularly in its dimensional stability and resistance to environmental factors.

Unlike nylon, polyester stretches very little when loaded. This creates a firmer lying surface and eliminates the need for constant readjustment after entry. The minimal stretch also means the hammock maintains its height off the ground more consistently when weighted.

Polyester’s standout characteristic is its exceptional UV resistance. While nylon can degrade after extended sun exposure (losing up to 30% of its strength), polyester maintains its integrity much longer in sunny environments. This makes it ideal for semi-permanent outdoor setups.

Weight capacities for polyester hammocks typically range from 300-400 pounds for single designs and 400-600 pounds for double hammocks, comparable to nylon but with greater longevity in outdoor conditions.

Cotton and Canvas

Traditional cotton hammocks offer a different experience and strength profile compared to synthetic options. Cotton provides exceptional breathability and comfort in hot conditions but trades some strength characteristics in the process.

Cotton hammocks typically feature lower weight capacities (200-300 pounds for single versions) unless constructed with significantly heavier fabric. The material absorbs moisture, making it heavier and potentially susceptible to mildew if not properly dried.

Canvas, a heavy-duty cotton variant, offers substantially higher strength. Canvas hammocks can support 350-500+ pounds in single designs and up to 800 pounds in reinforced double hammocks. This comes with significant trade-offs in weight and portability.

The natural feel of cotton and canvas appeals to traditionalists and those prioritizing breathability over absolute strength or weather resistance.

Rope/String Hammocks

Rope hammocks represent one of the oldest hammock designs, with strength determined by both material selection and weaving technique. Our rope hammock sets showcase various approaches to this classic design.

Synthetic rope hammocks (typically made from polyester or polypropylene) offer excellent weather resistance and strength while avoiding the mildew issues of natural fibers. Cotton rope provides comfort but requires more maintenance and typically offers lower weight capacity.

The weave pattern significantly impacts strength—tighter weaves with more connection points distribute weight more effectively. Traditional “Mayan” or “Mexican” weave patterns create a net-like structure that distributes weight across hundreds of intersection points.

Understanding Material Specifications: Denier, Thread Count, and Weave Patterns

When evaluating hammock materials, several technical specifications directly indicate strength potential. Understanding these measurements helps you make informed comparisons beyond basic material types.

Denier (D) measures the thickness of individual fibers in the fabric. Higher denier ratings indicate stronger, more durable (but also heavier) materials:

– 40D is considered ultralight

– 70D represents standard recreational quality

– 210D and above indicates heavy-duty construction

Thread Count (T) refers to the density of threads within a square inch of fabric. A 210T designation means there are 210 threads per square inch. Higher thread counts generally create stronger fabric, but the relationship isn’t always linear—fiber quality matters too.

Ripstop Construction features a distinctive grid pattern of reinforcement threads woven into the fabric. These thicker threads “stop rips” from spreading by containing damage to small sections. When examining ripstop nylon, you can actually see and feel these reinforcement grids spaced 1/4” to 1/8” apart.

Military-grade vs. commercial-grade designations can indicate different testing standards and quality control. Military-spec materials typically undergo more rigorous testing for consistent strength properties.

Choosing the perfect material for a lightweight outdoor hammock often involves balancing these specifications against your weight requirements and intended use. Single-layer construction prioritizes weight savings, while double-layer designs significantly increase strength by distributing force across two fabric sheets.

Understanding these specifications helps you see beyond marketing terms to the actual strength indicators that matter for safety.

Critical Construction Elements That Affect Weight Capacity

Even the strongest materials can fail if poorly constructed. Several construction elements play crucial roles in determining a hammock’s true weight capacity.

Stitching Quality

The quality of stitching often determines whether a hammock achieves its full strength potential:

– Stitch Type: Lock stitches resist unraveling better than chain stitches if one section fails

– Stitch Density: More stitches per inch create stronger seams (quality hammocks feature 8-10+ stitches per inch)

– Reinforced End Channels: Multiple rows of stitching at weight-bearing end points prevent catastrophic failures

Examining stitch quality reveals much about overall construction standards. Look for tight, consistent stitching with no loose threads or skipped stitches.

End Designs and Suspension Points

End construction dramatically impacts weight distribution and overall strength:

– Gathered ends concentrate force at suspension points

– Channel ends distribute weight more evenly across the fabric width

– Reinforcement patches at stress points prevent fabric tearing

– Whipping techniques (how rope ends are secured) prevent unraveling under load

These design elements often determine where failure occurs when weight limits are exceeded.

Suspension Systems

The suspension system must match or exceed the hammock body’s strength:

– Webbing straps typically offer greater strength than rope suspensions

– Connection points between suspension and hammock body create potential failure points

– Weight rating applies to the entire system, not just the fabric portion

Many hammock failures actually occur in the suspension system rather than the fabric itself.

Hardware Components

Hardware strength plays a critical role in overall system capacity:

– Carabiners are rated in kilonewtons (kN)—look for ratings of at least 12kN (approximately 2,700 lbs) for safety

– Spreader bars create different stress patterns than gathered end designs

– Rings, hooks, and other connection hardware create potential weak points

Our heavy-duty hammock sets feature reinforced construction elements specifically engineered for higher weight capacities.

Hammock Material & Weight Capacity Comparison Chart

| Material Type | Common Thickness | Key Strength Properties | Advantages | Disadvantages | Single Person Capacity | Double Person Capacity | Best Uses |

|---|---|---|---|---|---|---|---|

| Ripstop Nylon | 40D-210D | High tensile strength, tear resistant | Lightweight, packable, dries quickly | UV degradation over time, stretches when wet | 300-400 lbs | 400-550 lbs | Backpacking, camping, portable use |

| Polyester | 70D-210D | Excellent UV resistance, minimal stretch | Maintains shape under load, weather resistant | Less “give” than nylon, can feel stiffer | 300-400 lbs | 450-600 lbs | Permanent setups, sunny locations |

| Cotton | N/A (measured by weight) | Moderate strength, high comfort | Breathable, soft against skin | Absorbs moisture, mildew risk, heavier | 200-300 lbs | 300-450 lbs | Warm weather casual use, covered areas |

| Canvas | 10-15 oz per square yard | Very high tensile strength | Extremely durable, traditional feel | Heavy, slow-drying, limited portability | 350-500 lbs | 450-800 lbs | Long-term installations, heavy users |

| Synthetic Rope | 3-6mm diameter | Weather resistant, maintains strength when wet | Durable outdoors, traditional aesthetic | Less comfortable without pad, pressure points | 250-450 lbs | 400-600 lbs | Decorative settings, fixed installations |

| Cotton Rope | 4-8mm diameter | Good initial strength, comfortable | Traditional look, breathable | Weakens when wet, requires maintenance | 200-350 lbs | 300-450 lbs | Indoor use, covered patios |

Our collection of double two-person hammock sets offers options across multiple material types to accommodate different weight requirements and preferences.

How to Interpret Manufacturer Weight Ratings Safely

Manufacturer weight ratings require careful interpretation to ensure your safety. Understanding what these numbers really mean helps you make appropriate choices.

Static vs. Dynamic Reality: Most stated weight capacities refer to static loads—a person lying still in the hammock. However, real-world use involves dynamic forces. When you sit down quickly or adjust positions, you can momentarily exert forces 1.5-2 times your actual weight. This explains why a 200-pound person might experience failure in a hammock rated for exactly 200 pounds.

Safety Margins Matter: For comfortable, safe use, select a hammock with a weight capacity at least 25-50% higher than your actual weight. This provides a buffer for dynamic movements and accounts for additional items like phones or books you might bring into the hammock.

Marketing vs. Engineering: Some manufacturers provide conservative ratings based on extensive testing, while others may present best-case scenarios. Research brand reputation and testing standards when evaluating weight claims.

⚠️ Important Safety Note: “Double hammock” designations don’t automatically mean the product safely accommodates two adults. Always verify the specific weight capacity rather than assuming a double hammock supports twice the weight of a single model.

Understanding safe hammock weight limits helps prevent accidents and extends the life of your hammock. When in doubt, choose the higher capacity option for peace of mind.

Matching Materials to Your Specific Usage Needs

Selecting the right material for your specific weight requirements and usage patterns ensures both safety and satisfaction with your hammock purchase.

For Ultralight Backpacking (Under 200 lbs load)

Lightweight ripstop nylon offers the best strength-to-weight ratio for backpackers:

– Look for 40D-70D ripstop nylon with quality stitching

– Consider that your total load includes your body weight plus gear

– Single-layer construction maximizes weight savings

– Remember to account for a 25% safety margin above your actual weight

For a 150-pound person, a hammock rated for at least 200 pounds provides an appropriate safety buffer while minimizing pack weight.

For General Camping (200-300 lbs load)

Mid-weight materials balance durability with reasonable portability:

– 70D nylon or polyester provides excellent all-around performance

– Double-stitched seams enhance longevity

– Consider polyester for better UV resistance in sunny environments

– Webbing suspension systems distribute weight more effectively than rope suspensions

These materials provide years of reliable service for average-weight users in varied environments.

For Heavy-Duty Use (300+ lbs load)

Users requiring higher weight capacities should prioritize materials and construction specifically designed for strength:

– 210D or heavier fabrics provide necessary support

– Double-layer hammock construction dramatically increases weight capacity

– Look for triple-stitched seams and reinforced attachment points

– Wide webbing suspension (1” minimum) distributes forces more effectively

The ultimate guide for hammocks for heavier individuals provides detailed recommendations for selecting appropriate high-capacity hammocks.

For Two-Person Hammocks

Accommodating two people safely requires specific considerations beyond simply doubling capacity:

– Look for hammocks explicitly rated for 450+ pounds

– Wider designs (6.5+ feet) provide necessary space

– Double-layer construction provides additional stability

– Consider polyester for minimal stretch when supporting variable weights

Remember that dynamic forces increase with two moving occupants, making generous safety margins even more important.

Safety Inspection: Signs Your Hammock May No Longer Support Its Rated Weight

Regular inspection helps identify when your hammock no longer provides its original weight capacity. Environmental exposure and regular use gradually reduce strength over time.

Nylon Warning Signs:

– Significant color fading (indicates UV damage)

– Visible thinning in high-stress areas

– Permanent stretch marks or deformation

– Fraying around stitching or suspension points

Polyester Warning Signs:

– Excessive pilling on the surface

– Abraded areas appearing shiny or smooth

– Stiffening of originally supple fabric

– Loose or unraveling stitching

Cotton/Canvas Warning Signs:

– Mildew spots or discoloration

– Fabric that feels thinner or less substantial

– Excessive permanent stretching

– Visible fiber breakdown or “fuzzy” appearance

Rope Hammock Warning Signs:

– Frayed or broken strands

– Significant color changes

– Stiff or brittle texture

– Visible thinning at intersection points

Our fabric hammock sets are designed for durability, but even the highest quality materials require occasional inspection to ensure continued safety.

Regardless of apparent condition, consider replacing any hammock that:

– Has experienced a significant failure, even if repaired

– Has been exposed to harsh weather for extended periods

– Is more than 5-7 years old with regular use

– Shows significant wear at critical stress points

Classic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

$286.31 Select options This product has multiple variants. The options may be chosen on the product pageDouble / Two Person Hammock Sets, Rope Hammock Sets

Double Traditional Cotton Rope Hammock with Extension Chains – 450 lbs Capacity for Backyard & Patio$292.98 Select options This product has multiple variants. The options may be chosen on the product pageHeavy Duty Hammock Sets, Wooden Arc Stand Hammock Sets

$878.66 Select options This product has multiple variants. The options may be chosen on the product page

Frequently Asked Questions About Hammock Materials and Weight Capacity

Does thread count or denier have more impact on strength?

Both measurements matter but serve different purposes. Denier indicates fiber thickness and directly correlates with strength—higher denier means stronger individual threads. Thread count measures density (threads per square inch) and affects overall fabric performance. For maximum strength, look for both high denier (70D+) and high thread count (210T+).

Are spreader bar hammocks stronger than gathered-end designs?

Neither design is inherently stronger—the difference lies in how weight is distributed. Spreader bar designs distribute weight more evenly across the fabric width but create different stress points where the bars attach. Gathered-end designs concentrate force at suspension points but often use reinforced construction in these areas. Our quilted fabric hammock sets demonstrate how different designs address weight distribution challenges.

Can I modify my hammock to increase its weight capacity?

Most DIY modifications risk compromising the engineered safety of your hammock. Adding additional suspension points, reinforcing stitching with inexpert techniques, or attaching non-rated hardware often creates new weak points rather than strengthening the system. For higher weight capacity, purchasing a properly designed heavy-duty hammock is safer than modifying existing equipment.

Why do hammock capacities vary so much between manufacturers?

Variations stem from differences in:

– Testing methodologies (static vs. dynamic load testing)

– Safety margin philosophy (conservative vs. marketing-oriented)

– Whether ratings include or exclude suspension system capacity

– Definition of “failure” (catastrophic failure vs. excessive stretch)

Established manufacturers with extensive testing facilities typically provide more reliable ratings than newer market entrants.

Is nylon or polyester stronger for hammocks?

At equivalent denier ratings, nylon typically offers slightly higher tensile strength than polyester. However, polyester maintains its strength better over time when exposed to UV light and moisture. For short-term absolute strength, nylon has an edge. For long-term strength retention in outdoor conditions, polyester often performs better. The practical difference becomes significant only in extreme conditions or after extended use.

The Environmental Impact of Different Hammock Materials

The materials used in hammock construction not only affect strength and durability but also have varying environmental footprints worth considering in your purchasing decision.

Natural materials like cotton offer biodegradability advantages but typically require more water and pesticides during production than synthetic alternatives. Cotton hammocks will eventually decompose at the end of their lifecycle, unlike synthetic options that may persist in landfills for decades.

Synthetic materials like nylon and polyester require petroleum resources for production but typically create longer-lasting products. This durability factor means fewer replacements over time, potentially offsetting the initial environmental impact through extended product lifespan.

From an environmental perspective, durability becomes an important sustainability factor. Higher-quality hammocks that last 5-10 years create less waste than budget options requiring replacement after 1-2 seasons, regardless of material.

Some manufacturers now offer recycled polyester hammocks, which repurpose plastic waste into new fibers. These options reduce virgin plastic production while maintaining strength characteristics similar to traditional polyester.

Our spreader bar hammock sets represent diverse material choices, allowing you to select options aligned with both your comfort needs and environmental values.

Conclusion: Making an Informed Material Choice for Safety and Enjoyment

The relationship between hammock materials and weight capacity directly impacts both safety and enjoyment of your hammock experience. By understanding how different materials, construction techniques, and specifications contribute to overall strength, you can make informed decisions that ensure your relaxation remains worry-free.

Remember these key takeaways:

– Choose hammocks with weight capacities at least 25-50% above your actual needs

– Consider your usage environment when selecting materials (UV exposure, moisture, etc.)

– Recognize that the entire system’s strength depends on multiple factors working together

– Regularly inspect your hammock for signs of degradation or damage

– Replace any hammock showing significant wear at stress points

Outside Luxe offers hammocks designed with these principles in mind, ensuring you receive products engineered for both comfort and safety. By selecting appropriate materials and respecting weight limitations, your hammock will provide years of reliable relaxation wherever your adventures take you.