Understanding the Importance of Material Selection for Outdoor Stands

When investing in premium outdoor equipment, the materials used in heavy-duty stands make all the difference between a product that lasts for years and one that quickly succumbs to the elements. “Heavy-duty” refers to stands designed to support substantial weight consistently while “weather-resistant” indicates the ability to withstand prolonged exposure to various environmental conditions without significant degradation.

Selecting the right materials for outdoor stands isn’t merely about aesthetics—it’s a crucial decision affecting safety, functionality, and long-term value. Quality weather-resistant materials can extend stand life by 5-10 years compared to standard alternatives, representing significant value for discerning consumers.

Outdoor stands face relentless environmental challenges:

– Constant UV radiation exposure causing material breakdown

– Moisture penetration leading to internal corrosion or rot

– Temperature fluctuations creating expansion and contraction stress

– Wind forces testing structural integrity

Finding the right balance between indoor and outdoor hammock placement requires understanding how materials perform in various conditions. The right material choice not only ensures longevity but also maintains the aesthetic appeal that premium outdoor products promise.

Critical Performance Factors for Outdoor Stand Materials

When evaluating materials for weather-resistant, heavy-duty stands, several key performance factors determine how well they’ll withstand the elements while maintaining their functionality and appearance.

Strength and Load-Bearing Capacity

– Must support specified weight limits consistently (typically 300-600 pounds)

– Should maintain structural integrity without bending or warping

– Needs to withstand dynamic forces from movement and use

Corrosion and Rust Resistance

– Ability to resist oxidation when exposed to moisture

– Protection against salt exposure in coastal environments

– Resistance to chemical contaminants in urban settings

UV Radiation Protection

– Prevention of color fading and material degradation

– Maintenance of physical properties despite sun exposure

– UV-stabilized materials or protective coatings

Temperature Tolerance

– Materials must withstand temperature ranges from 0°F to 120°F (-18°C to 49°C) without structural compromise

– Resistance to expansion/contraction damage during freeze-thaw cycles

– Prevention of brittleness in extreme cold or softening in extreme heat

Moisture and Water Resistance

– Ability to repel water rather than absorb it

– Prevention of internal moisture damage like rot or mildew

– Resistance to humidity-related issues

Understanding whether it’s okay to leave a hammock outside largely depends on these material factors, especially when considering the stands that support them. Additionally, consider:

- Wind resistance: Balance between weight and stability

- Impact resistance: Ability to withstand accidental bumps without denting or breaking

- Maintenance requirements: Time and effort needed to maintain appearance and functionality

- Weight considerations: Portability versus stability tradeoffs

- Cost-effectiveness: Initial investment versus lifetime value

Premium Metals for Long-Lasting Outdoor Stands

Stainless Steel (Grades 304 and 316)

Stainless steel stands at the forefront of premium materials for weather-resistant outdoor stands, offering exceptional durability and corrosion resistance. The difference between grades is significant:

- Grade 304 (18/8) provides excellent corrosion resistance for standard outdoor use, containing 18% chromium and 8% nickel

- Grade 316 (Marine Grade) offers superior protection in harsh environments, especially coastal areas, with added molybdenum for enhanced corrosion resistance

Marine-grade 316 stainless steel stands can support loads up to 600 pounds (272 kg) while resisting saltwater corrosion, making them ideal for coastal properties or pool areas.

Strength Characteristics:

– High tensile strength resisting bending and deformation

– Excellent fatigue resistance for repeated loading

– Superior impact resistance compared to aluminum

Aesthetic Qualities:

– Available in polished, brushed, or matte finishes

– Maintains appearance with minimal maintenance

– Modern, premium look that complements luxury outdoor spaces

For heavy-duty hammock sets that see frequent use, stainless steel provides unmatched peace of mind regarding stability and longevity, though at a higher price point than other options.

Aluminum and Aluminum Alloys

Aluminum offers an excellent balance of strength and weight, making it particularly valuable for stands that may need occasional repositioning or seasonal storage.

Key Advantages:

– Approximately one-third the weight of steel with impressive strength

– Naturally forms a protective oxide layer when exposed to air

– Will not rust like ferrous metals, though it can corrode in certain conditions

– Ideal for creating portable yet sturdy stands

Premium aluminum stands often utilize aircraft-grade alloys (like 6061-T6) that significantly enhance strength while maintaining lightweight properties. These alloys contain small amounts of silicon, magnesium, and other elements to improve performance characteristics.

Finish Options:

– Anodizing: Creates a harder, more durable colored surface that resists scratching

– Powder coating: Adds color options while enhancing weather resistance

– Textured finishes: Provides better grip and conceals minor scratches

Aluminum stands excel in situations requiring a balance between portability and durability, though they typically support slightly lower weight capacities than steel options.

Galvanized and Powder-Coated Steel

For maximum strength at a more accessible price point, galvanized and powder-coated steel offers compelling advantages:

Galvanized Steel Protection:

– Hot-dip galvanizing creates a zinc coating that sacrificially protects the steel beneath

– Provides excellent corrosion resistance for 15-20+ years in most environments

– More affordable than stainless steel while offering substantial durability

Powder-Coating Benefits:

– Applied electrostatically and then cured under heat

– Creates a harder finish than conventional paint

– Available in countless colors and textures

– Can be applied over galvanized steel for maximum protection

When designed properly, powder-coated steel stands can support weights exceeding 500 pounds while resisting environmental damage, making them excellent options for permanent outdoor installations.

Maintenance Considerations:

– Inspect occasionally for scratches that might compromise the coating

– Touch up any damaged areas promptly to prevent corrosion spread

– Clean periodically with mild soap and water to maintain appearance

Advanced Composites and Engineered Materials

Fiber-Reinforced Polymers (FRP)

Modern fiber-reinforced polymers represent the cutting edge of materials technology for outdoor applications, combining lightweight properties with exceptional strength and weather resistance.

Key Properties:

– Fiberglass, carbon fiber, or aramid fibers embedded in polymer matrices

– Strength-to-weight ratios that can exceed steel

– Complete immunity to rust and corrosion

– Excellent UV stability when properly formulated

FRP materials excel in applications where weight is a critical factor but strength cannot be compromised. High-end outdoor products increasingly incorporate these materials for their combination of performance benefits.

| Material | Weight (relative) | Corrosion Resistance | UV Stability | Cost |

|---|---|---|---|---|

| Steel | 100% | Moderate (needs coating) | Excellent with coating | $ |

| Aluminum | 35% | Good | Good with anodizing | $$ |

| FRP | 25% | Excellent | Excellent | $$$ |

These advanced materials are particularly valuable in indoor and outdoor hammock safety applications where reliability is paramount, but transportability is also desired.

High-Density Polyethylene (HDPE)

HDPE represents one of the most versatile engineered plastics for outdoor applications, offering exceptional weather resistance and durability:

Distinctive Qualities:

– Complete waterproof properties

– Excellent chemical resistance

– Highly resistant to UV damage when properly formulated

– Can incorporate recycled materials for sustainability

While not typically used for entire stand structures, HDPE components are often incorporated into hybrid designs, particularly for connection points, feet, or decorative elements. These components can last for decades without significant degradation.

Stability Solutions:

– Often reinforced with internal metal structures for enhanced weight capacity

– Molded with ribbing and structural elements for increased rigidity

– Available with additives to increase density and stability

Innovative Composite Materials

The outdoor market continues to evolve with new material developments offering unique combinations of properties:

- Wood-polymer composites combining natural wood fibers with protective polymers

- Hybrid metal-composite structures utilizing the best properties of each material class

- Engineered bamboo products offering sustainable alternatives with impressive strength

These innovative materials often provide distinctive aesthetic benefits while maintaining the performance characteristics demanded by premium outdoor applications.

Natural Materials with Enhanced Weather Protection

Premium Hardwoods for Outdoor Applications

When properly selected and treated, certain hardwoods offer natural weather resistance and unmatched aesthetic appeal for outdoor stand applications.

Naturally Resistant Species:

– Teak: Contains natural oils that repel water and resist insects, considered the gold standard for outdoor hardwoods with lifespans exceeding 50 years

– Western Red Cedar: Contains natural compounds that resist decay and insect damage

– Ipe (Brazilian Walnut): Extremely dense hardwood with natural resistance to decay, insects, and mold

The inherent beauty of wooden hammocks stands provides a warmth and organic quality that manufactured materials cannot replicate. The natural variations in grain pattern ensure each piece has a unique character.

Sustainability Considerations:

– Look for FSC certification ensuring responsible forest management

– Consider reclaimed or recycled wood options for reduced environmental impact

– Evaluate local vs. exotic species balancing transportation impact against durability

Aesthetic Integration:

– Natural wood blends harmoniously with landscape elements

– Develops a distinctive patina over time that many find appealing

– Complements both traditional and contemporary outdoor design schemes

Modern Wood Treatments and Protectants

Today’s wood treatments dramatically extend the lifespan and performance of wooden stands beyond what was possible in previous generations:

Advanced Protection Technologies:

– Pressure-treatment forcing preservatives deep into wood fibers

– Water-based sealants that penetrate while allowing wood to breathe

– UV-inhibiting finishes preventing sun damage and color fading

– Nano-particle formulations creating molecular barriers against moisture

With proper application and maintenance, these treatments can extend the functional outdoor life of wooden stands by 10-15 years compared to untreated versions.

Maintenance Schedule:

– Annual inspection for finish integrity

– Reapplication of sealants every 1-3 years depending on exposure

– Prompt attention to any areas showing signs of water absorption

– Seasonal cleaning to prevent organic matter accumulation

Protective Finishes and Treatments for Enhanced Durability

Advanced Powder Coating Technologies

Modern powder coating represents a quantum leap beyond traditional paint, offering superior protection for metal components in outdoor applications.

Process Benefits:

– Electrostatic application ensures complete coverage even on complex shapes

– Thermal bonding creates a “skin” that is substantially more durable than wet paint

– Zero VOC emissions making it environmentally superior to solvent-based paints

– Single-coat application provides excellent thickness and consistency

Weather Resistance Properties:

– Superior color retention even in high-UV environments

– Excellent resistance to chipping, scratching, and impact damage

– Available in textured finishes that conceal minor surface imperfections

– Can include antimicrobial additives for additional protection

The debate between steel vs. wood hammock stands often centers on durability, where modern powder coatings have significantly improved steel’s long-term performance in outdoor settings.

Specialized Marine-Grade Finishes

For extreme environments, particularly coastal areas with salt spray exposure, specialized marine-grade finishes offer exceptional protection:

- Multiple-layer systems specifically designed to withstand salt corrosion

- Zinc-rich primers creating sacrificial protection layers

- Elastomeric topcoats allowing for thermal expansion without cracking

- UV-stabilized formulations preventing breakdown from sun exposure

Marine-grade powder coating can extend steel lifespan by up to 300% in coastal environments compared to standard finishes, representing a substantial value enhancement for premium outdoor products.

Nano-Coatings and Emerging Technologies

The frontier of protective finishes includes remarkable nano-scale technologies that create molecular barriers against environmental damage:

- Hydrophobic (water-repelling) surfaces that prevent moisture penetration

- Self-cleaning properties that minimize maintenance requirements

- Enhanced scratch resistance through molecular hardening

- Transparent applications that maintain the original material appearance

While still emerging in mainstream outdoor products, these technologies are increasingly available in premium offerings where performance justifies their additional cost.

Dark Wood Hammock Sets, Porch Swing Chair Sets

$653.82 Select options This product has multiple variants. The options may be chosen on the product pageLight Wood Hammock Sets, Swinging Hammock Chair Sets

$1,359.35 Select options This product has multiple variants. The options may be chosen on the product pageClassic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

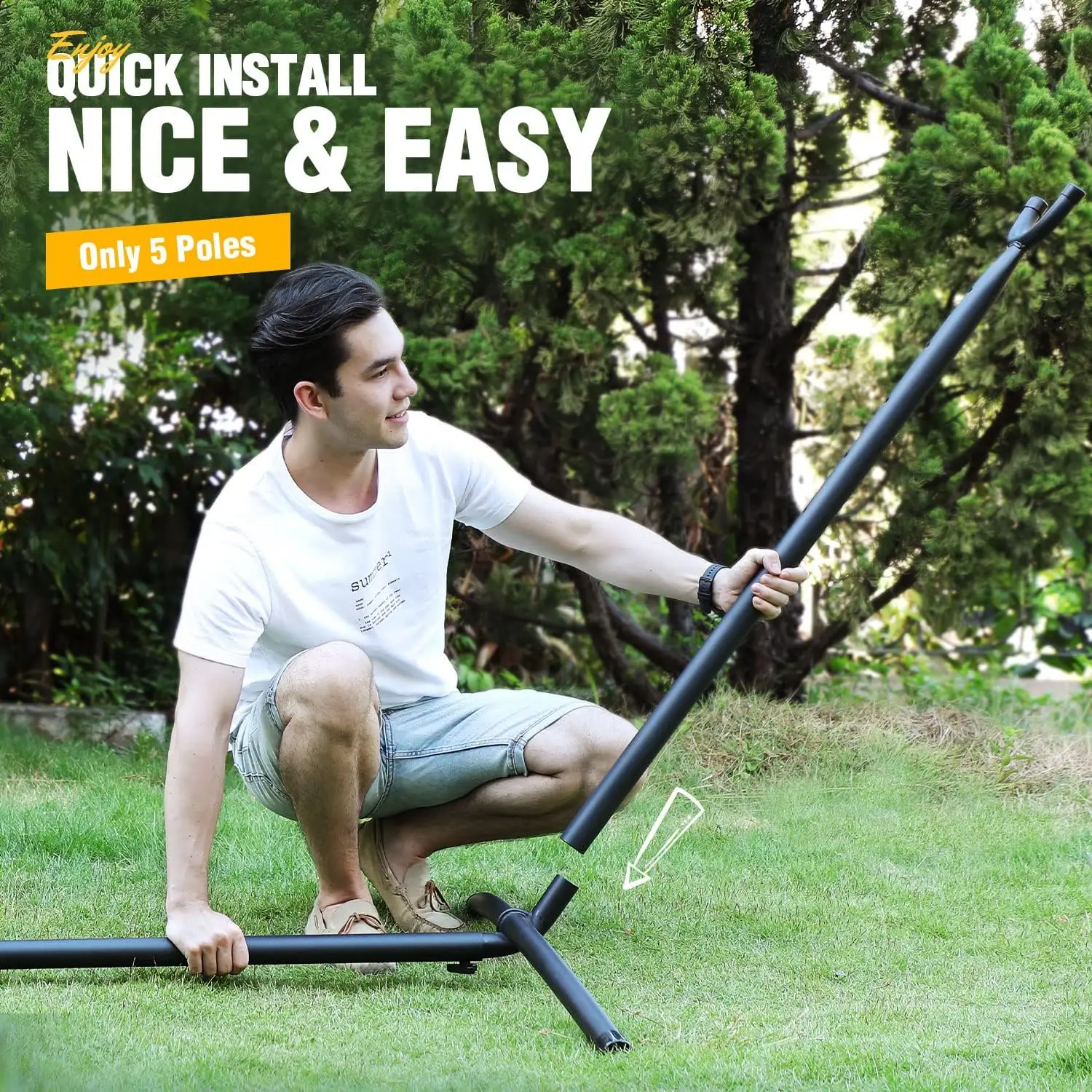

$286.31 Select options This product has multiple variants. The options may be chosen on the product pageFolding Hammock Sets, Quick Setup Hammock Sets

Price range: $305.52 through $583.27 Select options This product has multiple variants. The options may be chosen on the product page

Material Selection Guide by Environmental Conditions

Coastal and High-Salt Environments

Coastal areas present perhaps the most challenging conditions for outdoor stands due to constant salt spray, high humidity, and often strong UV exposure.

Recommended Materials:

– 316 (marine-grade) stainless steel

– Properly sealed teak or ipe hardwoods

– Specialized aluminum alloys with marine-grade anodizing

– HDPE components for non-structural elements

Materials to Avoid:

– Standard carbon steel (even with basic galvanizing)

– Woods without proper marine-grade sealants

– Standard powder coatings not rated for marine use

Regular rinsing with fresh water significantly extends the life of any material in coastal settings by removing salt accumulation before it can cause damage.

Extreme Temperature Environments

Desert regions with intense sun and dramatic temperature swings or cold northern areas with freeze-thaw cycles require specific material considerations.

For portable hammocks stands that might face various environmental conditions, material selection becomes even more critical:

Hot Desert Regions:

– Materials with excellent UV stability

– Heat-reflective finishes to prevent excessive heating

– Materials that won’t become too hot to touch in direct sun

– Protection against drying and cracking

Cold/Winter Regions:

– Materials that maintain flexibility in low temperatures

– Finishes that can accommodate expansion/contraction

– Corrosion protection for exposure to road salts and deicers

– Materials that won’t become brittle when cold

High-Humidity and Tropical Environments

Tropical and high-humidity environments create perfect conditions for organic growth and accelerated deterioration of many materials.

Key Considerations:

– Resistance to mold, mildew, and fungal growth

– Materials that don’t absorb or trap moisture

– Ventilation features in design to promote drying

– Resistance to insect damage (particularly for wood components)

Stainless steel, aluminum, and properly treated hardwoods like teak perform exceptionally well in these conditions, while some coated steels may struggle without frequent maintenance.

Urban and Industrial Environments

Urban settings present unique challenges including pollution, acid rain, bird droppings, and other contaminants that can damage outdoor materials.

Material Recommendations:

– Easy-clean surfaces that don’t trap particulates

– Chemical-resistant finishes for pollution exposure

– Darker colors or textured finishes that conceal particulate buildup

– Materials resistant to staining from bird droppings or tree sap

Comparative Analysis of Top Materials for Premium Stands

| Material | Load Capacity | Weather Resistance | Lifespan | Maintenance | Aesthetics | Price Range | Sustainability |

|---|---|---|---|---|---|---|---|

| 316 Stainless Steel | 5/5 | 5/5 | 5/5 | 4/5 | 4/5 | $$$$ | 3/5 |

| 304 Stainless Steel | 5/5 | 4/5 | 4/5 | 4/5 | 4/5 | $$$ | 3/5 |

| Powder-Coated Steel | 5/5 | 3/5 | 3/5 | 2/5 | 4/5 | $$ | 3/5 |

| Aluminum Alloy | 3/5 | 4/5 | 4/5 | 4/5 | 3/5 | $$$ | 4/5 |

| Teak Hardwood | 4/5 | 4/5 | 4/5 | 2/5 | 5/5 | $$$$ | 3/5* |

| Composite Materials | 3/5 | 4/5 | 4/5 | 5/5 | 3/5 | $$$ | 5/5 |

*When sourced responsibly with proper certification

When considering lifetime costs, materials with higher initial prices often provide better value through extended lifespans and reduced maintenance requirements. For example, premium teak or 316 stainless steel stands might cost twice as much initially but last three times longer than basic alternatives.

The waterproof materials hammocks protection guide demonstrates that proper material selection for both the hammock and stand creates a synergistic effect, maximizing the overall system’s durability.

How to Evaluate Material Quality in Ready-Made Stands

Assessing material quality before purchasing can be challenging but following these evaluation steps will help ensure you receive a genuinely premium product:

Visual Inspection Techniques:

– Look for consistent finish without bubbling, flaking, or uneven application

– Examine weld points for neatness and proper execution

– Check for smooth edges and corners indicating quality manufacturing

– Assess weight as an indicator of material thickness and quality

Stability and Durability Testing:

– Gently rock the assembled stand to check for wobbling or loose connections

– Apply pressure at different points to ensure even weight distribution

– Examine connection points for robust engineering and quality hardware

– Test any moving parts for smooth operation without binding

Quality stainless steel stands will have consistent weld points without discoloration, while wood products should show attention to detail in joinery and finish application.

When considering spreader bar hammock sets, pay special attention to the connection between the spreader bars and the stand, as this junction faces significant stress during use.

Material Certification Questions:

– Ask about specific grade designations (e.g., 304 vs. 316 stainless)

– Request information on coating thickness for powder-coated products

– Inquire about wood species and specific treatment processes

– Look for quality certifications from recognized industry organizations

FAQ: Essential Questions About Weather-Resistant Stand Materials

What is the most rust-proof material for outdoor hammock stands?

316 marine-grade stainless steel offers the highest level of corrosion resistance for metal stands. Its molybdenum content creates superior protection against rust, particularly in coastal environments. For a more budget-friendly option, high-quality aluminum with proper anodizing also provides excellent rust resistance.

How can I protect my wooden stand during winter months?

For wooden stands, apply a fresh coat of marine-grade sealant before winter storage. Ideally, store the stand in a covered area away from direct snow and rain. If outdoor storage is necessary, use a breathable cover that prevents moisture accumulation while allowing airflow. Elevate the stand slightly off the ground to prevent moisture wicking from soil contact.

Is aluminum strong enough for heavy-duty applications?

Quality aluminum alloys can indeed support substantial weight when properly engineered. Look for aircraft-grade aluminum (6061-T6) and designs that incorporate structural reinforcement at key stress points. While pound-for-pound aluminum is not as strong as steel, well-designed aluminum stands can safely support 300+ pounds, making them suitable for most heavy-duty applications while offering significant weight advantages.

What’s the best low-maintenance material for coastal environments?

HDPE (High-Density Polyethylene) components or 316 stainless steel offer the lowest maintenance requirements in coastal settings. Both materials resist salt corrosion naturally without requiring special treatments or frequent cleaning. Quality teak with proper initial sealing also performs exceptionally well with minimal maintenance beyond occasional cleaning.

How often should I inspect my outdoor stand for weather damage?

Perform visual inspections at the beginning and end of each outdoor season. Additionally, check after extreme weather events (heavy storms, unusually high winds, etc.). Pay special attention to connection points, areas where water might pool, and locations showing finish wear. Catching minor issues early prevents more significant problems later.

Can I leave my premium stand outdoors year-round?

Premium stands made from marine-grade stainless steel, properly treated teak, or high-quality composites can indeed remain outdoors year-round in most climates. However, even these materials benefit from periodic maintenance and cleaning. In regions with extreme winters, covering or storing any stand type will extend its aesthetic life, even if the structural integrity isn’t compromised.

Why Material Quality Matters for Premium Relaxation Products

The materials used in your outdoor stand directly impact your relaxation experience in ways that extend far beyond mere durability. When you settle into a hammock supported by premium materials, you’re experiencing the culmination of thoughtful engineering and quality craftsmanship.

Safety and peace of mind represent perhaps the most important yet least discussed benefits of premium materials. When suspended above the ground, the subconscious confidence that comes from knowing your stand is built from materials that won’t suddenly fail allows for true relaxation without nagging concerns.

The top features of heavy-duty hammock frames illustrate how material selection affects overall performance. Premium materials maintain their appearance over time, ensuring that your outdoor space continues to reflect your aesthetic standards years after purchase.

Consider the experience contrast: settling into a hammock on a stand that creaks, flexes excessively, or shows visible deterioration creates tension rather than relaxation. Conversely, a stand that remains rock-solid, visually appealing, and functionally flawless year after year enhances every moment spent enjoying your outdoor retreat.

At Outside Luxe, we understand that true luxury comes not just from initial appearance but from enduring quality that proves its value with each passing season. Premium materials don’t just last longer—they provide a consistently superior experience throughout their extended lifetime.