Why Invest in a Heavy-Duty Hammock Stand for Your Large Hammock

Choosing the right support for your large hammock isn’t just about comfort—it’s about safety. Standard hammock stands simply aren’t designed to handle the weight distribution and stress that comes with larger hammocks or multiple users. Without proper support, you risk sudden collapses that can cause injuries, damage your hammock, or even harm nearby property.

A quality heavy-duty hammock stand transforms how you experience relaxation. Unlike relying on perfectly spaced trees or permanent posts, a proper stand gives you freedom to place your hammock wherever you desire—patios, lawns, indoor spaces, or even rental properties where permanent fixtures aren’t an option. Most importantly, heavy-duty stands are engineered specifically to distribute weight properly across their structure, providing stability that standard options simply can’t match.

Key benefits of investing in a proper heavy-duty stand include:

* Safety margins that typically support 450-800+ lbs (204-363+ kg)

* Versatile placement options independent of existing structures

* Stability on various surfaces from grass to concrete

* Portability between different locations (even heavy-duty models often disassemble)

* Extended hammock lifespan (properly supported hammocks last 2-3 times longer)

* Peace of mind during deep relaxation

Finding the perfect spot for your hammock setup becomes much simpler with proper indoor outdoor hammock placement guidance. For those seeking complete solutions that pair large hammocks with appropriate stands, our selection of heavy-duty hammock sets offers pre-matched combinations tested for optimal safety and comfort.

Understanding Weight Capacity: Beyond the Numbers

When manufacturers specify weight capacity for hammock stands, they’re providing a critical safety parameter that requires proper interpretation. The true load capacity you need goes beyond just your body weight—it involves a complete calculation of all potential forces on the stand.

To determine the minimum weight capacity needed for your situation, use this formula:

1. Add the weight of all potential users

2. Add the weight of the hammock itself

3. Include a safety margin of 20-25%

For example: If you weigh 200 lbs (91 kg), your partner weighs 180 lbs (82 kg), and your hammock weighs 15 lbs (7 kg), your calculation would be 200 + 180 + 15 = 395 lbs. Adding a 25% safety margin brings your minimum required capacity to 494 lbs (224 kg).

It’s also important to understand the difference between static and dynamic weight ratings:

* Static weight is the capacity when users are lying still

* Dynamic weight accounts for movement, swinging, and entry/exit forces

Many accidents occur because users don’t account for these dynamic forces that can temporarily double the pressure on certain parts of the stand. Quality stands are designed with these forces in mind and often carry industry certifications like ASTM or CE markings that validate their safety claims.

Weight distribution principles also matter significantly. The center point of a hammock bears the most weight, and the force is directed both downward and outward, creating leverage that tests the stand’s structural integrity. This explains why a poorly designed 500 lb capacity stand might fail under 400 lbs of actual weight if the design doesn’t properly manage these distribution forces.

Understanding the strongest materials for hammock stands can help you make informed choices about durability and support. For comprehensive guidance on all safety aspects, referring to hammock installation requirements before setup ensures your relaxation system meets necessary safety standards.

Material Strength: Comparing Options for Maximum Support

The material of your hammock stand directly determines its strength, durability, and weight capacity. Each option offers distinct advantages for supporting large hammocks:

Powder-Coated Steel

* Highest tensile strength-to-cost ratio

* Superior weight capacity (typically 450-800+ lbs)

* Resistant to bending and warping under load

* Relatively affordable compared to other heavy-duty options

* Requires protection against rust and corrosion

Stainless Steel

* Exceptional strength combined with superior weather resistance

* Premium durability in all environments, especially coastal areas

* Maintains structural integrity even with exposure to elements

* Higher price point justified by longevity and minimal maintenance

* Slightly lower weight capacity than standard steel in some designs

Hardwoods (Teak, Cypress, Oak)

* Natural aesthetic appeal with impressive strength

* Engineered designs can support 400-600 lbs when properly constructed

* Laminated or multi-layer construction enhances load capacity

* Requires proper sealing and maintenance for outdoor durability

* Premium options offer excellent longevity with proper care

Aluminum Alloys

* Best strength-to-weight ratio (easier to move while maintaining strength)

* Modern alloys achieve surprising support capacities (400-500 lbs)

* Natural corrosion resistance ideal for outdoor use

* Often used in portable heavy-duty designs

* Typically costs more than standard steel options

Material thickness plays a crucial role regardless of the base material. For steel stands, look for 12-14 gauge tubing for adequate support of large hammocks. Thinner materials (higher gauge numbers) significantly reduce weight capacity and long-term durability.

| Material Type | Max Typical Weight Capacity | Strength-to-Weight Ratio | Structural Integrity Rating | Best Applications |

|---|---|---|---|---|

| Powder-Coated Steel | 800+ lbs (363+ kg) | Good | Excellent | Permanent outdoor/indoor setups |

| Stainless Steel | 700+ lbs (317+ kg) | Good | Excellent | Coastal environments, premium installations |

| Hardwoods | 600 lbs (272 kg) | Moderate | Very Good | Aesthetic settings, covered patios |

| Aluminum Alloy | 500 lbs (227 kg) | Excellent | Good | Portable heavy-duty, lightweight needs |

The connection between material choice and long-term enjoyment is significant—investing in proper materials ensures years of durable hammock stand relaxation without worry about structural failure.

Structural Design Elements That Enhance Load-Bearing Capacity

The engineering behind a hammock stand is just as important as its material composition. Several key design elements determine how effectively a stand distributes and supports weight:

Support Beam Configuration

The shape and arrangement of the main support beams significantly impact strength. Look for:

* Tubular steel with thick walls (1.5-2 inch diameter)

* I-beam or reinforced box designs that resist bending

* Truss-style supports that distribute force across multiple points

* Solid (non-hollow) components at critical stress points

Connection Points and Joints

The weakest links in most stands are where components connect. Premium heavy-duty stands feature:

* Welded joints rather than just bolted connections

* Reinforced connection plates that spread force over larger areas

* Double-bolted junctions with lock washers to prevent loosening

* Steel gussets at corners for added structural integrity

Base Stability Structures

A wider footprint creates greater stability under load. Effective designs include:

* H-frame bases that resist tipping in multiple directions

* Wide-stance legs (typically 4-5 feet across)

* Outrigger supports that extend beyond the hammock attachment points

* Low center of gravity configurations

The engineering principle of triangulation is particularly important in hammock stand design. By creating triangular support structures within the frame, manufacturers significantly increase strength while minimizing material usage. This explains why some stands appear relatively lightweight yet support impressive loads.

Weight distribution systems in advanced models include features like:

* Curved support arms that direct force down through the main structure

* Graduated thickness with reinforcement at high-stress points

* Multiple contact points with the ground to spread weight evenly

* Chain or rope attachment systems that absorb and distribute dynamic forces

For those seeking stands specifically designed for shared relaxation, our double two-person hammock sets feature frames engineered with enhanced structural support for multiple users.

Size and Dimensional Compatibility for Large Hammocks

Finding the perfect size match between your large hammock and stand is essential for both safety and comfort. The dimensions must work together as a system to create proper support and the ideal relaxation experience.

Length Considerations

The relationship between hammock length and stand length follows specific ratios:

* Stand length should typically be 2 feet shorter than the total hammock length

* For large hammocks (11-15 feet), look for stands 9-13 feet in length

* Brazilian-style hammocks require more distance between support points than spreader bar models

* The optimal hang angle of 30° requires sufficient stand length to achieve

Width and Height Factors

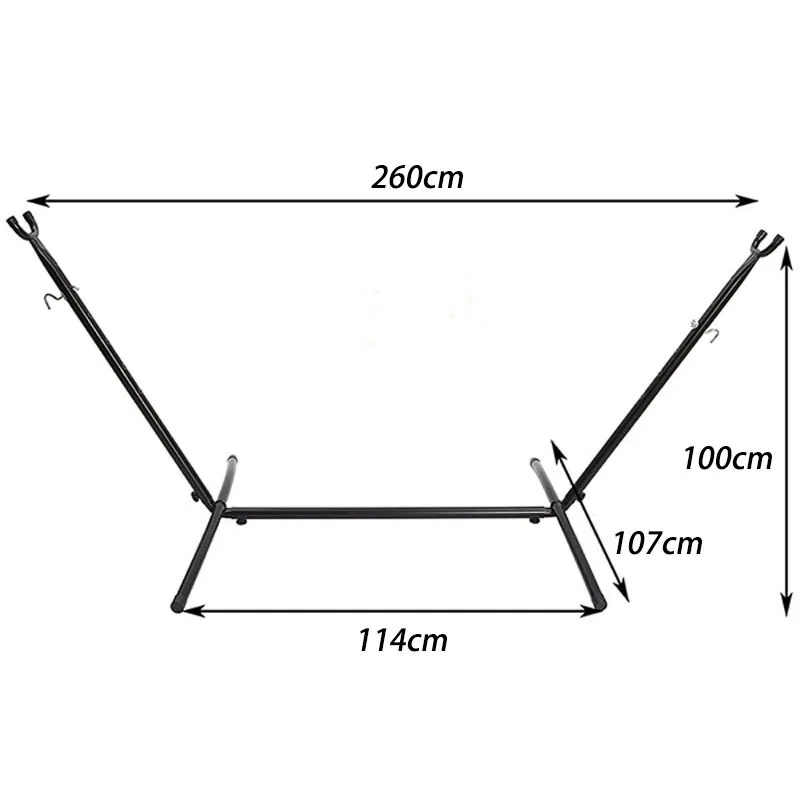

For extra-wide hammocks or multi-person models, additional dimensions matter:

* Stand width should accommodate the hammock’s fully spread width plus 10-12 inches

* Base width must be proportional to height to maintain stability

* Entry height (distance from ground to hammock edge) ideally falls between 18-22 inches for easy access

* Overall height should allow for proper sag (typically 48-60 inches at center posts)

Hammock-Stand Compatibility Table:

| Hammock Type | Hammock Length | Minimum Stand Length | Ideal Height | Base Width |

|---|---|---|---|---|

| Standard Large | 11-13 ft (3.4-4m) | 9-10 ft (2.7-3m) | 4 ft (1.2m) | 4 ft (1.2m) |

| Extra Large | 13-15 ft (4-4.6m) | 11-12 ft (3.4-3.7m) | 5 ft (1.5m) | 4.5 ft (1.4m) |

| Family Size | 15+ ft (4.6m+) | 13+ ft (4m+) | 5.5+ ft (1.7m+) | 5+ ft (1.5m+) |

| Spreader Bar XL | 13-14 ft (4-4.3m) | 15-16 ft (4.6-4.9m) | 4 ft (1.2m) | 4 ft (1.2m) |

The footprint required for heavy-duty stands is substantial—plan for approximately 2-3 feet beyond the actual stand dimensions for safe clearance on all sides. This ensures you have adequate space for entry and exit without obstructions.

For those seeking stands with ideal proportions for larger hammocks, our A-frame stand hammock sets offer properly engineered dimensions that eliminate guesswork in matching components.

Stability Features and Anti-Tip Technology

Stability is a critical safety factor for any hammock stand, particularly for large hammocks where weight distribution creates greater tipping potential. Advanced stands incorporate numerous features specifically designed to prevent accidents.

Base Design and Stance

The foundation of stability starts with the stand’s footprint:

* Wider stance bases resist tipping forces more effectively

* Heavy-duty models typically feature bases 4-5 feet wide

* Lower center of gravity designs naturally resist tipping

* H-frame configurations provide multi-directional stability

Anti-Tip Technologies

Premium stands incorporate specific features to enhance stability:

* Counterbalance weights built into base components

* Extended feet that project beyond the hammock’s swing radius

* Ground anchor points for permanent or temporary securing

* Anti-slip padding on feet to prevent sliding on smooth surfaces

Terrain Adaptation

Adapting to uneven surfaces is essential for outdoor stability:

* Adjustable feet with leveling mechanisms

* Articulating bases that conform to ground contours

* Wider contact points that distribute pressure on soft surfaces

* Stakes or pegs for securing on grass or soil

Understanding the physics of hammock use helps appreciate these features. When you enter or exit a hammock, you temporarily create significant leverage against one side of the stand. Without proper stability features, this momentary force can cause dangerous tipping. Similarly, shifting position while relaxing creates dynamic forces that constantly test the stand’s stability.

For indoor applications, stability concerns differ slightly, and proper setup becomes even more important. Understanding whether it’s safe to hang a hammock indoors helps you make appropriate stability choices for interior installations.

Weather Resistance and Outdoor Durability

For outdoor hammock stands, the ability to withstand environmental challenges directly impacts long-term safety and performance. Weather exposure can gradually compromise even the strongest materials if they’re not properly protected.

Metal Stand Protection

Most heavy-duty metal stands utilize specific treatments to combat corrosion:

* Powder coating creates a tough barrier against moisture and UV damage

* Galvanization bonds zinc to steel for superior rust prevention

* Oil-rubbed finishes require maintenance but can be restored

* Marine-grade treatments for coastal environments with salt air exposure

Climate-Specific Considerations

Different environments create unique challenges for hammock stands:

* Hot/humid climates accelerate corrosion and require enhanced protection

* Coastal areas with salt spray demand marine-grade materials or regular maintenance

* Freezing conditions can cause expansion damage in joints and connections

* Direct sun exposure degrades finishes and can weaken certain materials over time

Properly maintained heavy-duty stands can maintain their weight capacity for many years, but neglect accelerates degradation. For example, a quality powder-coated steel stand might maintain full strength for 7-10 years with basic care, while the same stand left untreated could show structural weakness in as little as 2-3 years in challenging environments.

For wooden stands, weather resistance requires different approaches:

* Waterproof sealants that penetrate the wood fibers

* UV-resistant finishes to prevent sun damage

* Regular reapplication of protective coatings

* Selection of naturally weather-resistant wood species

Understanding whether it’s okay to leave your hammock outside provides valuable guidance on protecting your entire relaxation system from weather damage.

Top 5 Heavy-Duty Hammock Stands for Large Hammocks

When selecting a heavy-duty stand for your large hammock, certain models stand out for their exceptional engineering and load-bearing capabilities. Here are five outstanding options that combine strength, stability, and quality construction:

1. Steel Frame H-Base XL Stand

This robust stand features a wide H-pattern base that creates exceptional stability while supporting impressive weights.

Key Features:

* Weight capacity: 600 lbs (272 kg)

* Material: Heavy-gauge powder-coated steel (12-gauge, 1.75” diameter)

* Length: 15 feet (4.6 m) – accommodates hammocks 13-15 feet long

* Reinforced connection points with double-bolted design

* Weather-resistant finish with UV protection

* Wide-stance legs with rubber stabilizing feet

Best For: Permanent outdoor installations requiring maximum stability and durability.

2. Portable Heavy-Duty Tubular Steel Stand

Despite its portable nature, this stand doesn’t compromise on strength, making it ideal for those who need flexibility and durability.

Key Features:

* Weight capacity: 550 lbs (249 kg)

* Material: Galvanized steel tubing with reinforced joints

* Length: 9.5 feet (2.9 m) – fits most large hammocks

* Quick-assembly design with no tools required

* Includes carrying case for transport

* Tapered leg design for enhanced stability

Best For: Those who need a combination of portability and exceptional strength.

3. Modern Curved Wood Heavy-Duty Stand

Blending aesthetics with function, this wooden stand uses laminated construction techniques for superior strength.

Key Features:

* Weight capacity: 500 lbs (227 kg)

* Material: Multiple layers of treated cypress with weather-resistant finish

* Length: 15 feet (4.6 m)

* Architectural curved design for superior weight distribution

* Stainless steel hardware throughout

* Low center of gravity for enhanced stability

Best For: Design-conscious users who want natural materials without sacrificing capacity.

4. All-Weather Stainless Steel Premium Stand

This premium option represents the ultimate in durability and corrosion resistance for challenging environments.

Key Features:

* Weight capacity: 650 lbs (295 kg)

* Material: Marine-grade 316 stainless steel

* Length: 12 feet (3.7 m)

* Specialized welded joints for maximum strength

* Built-in stabilizers for uneven terrain

* Lifetime warranty against structural failure

Best For: Coastal locations and users seeking the absolute best in long-term durability.

5. Adjustable XL Heavy-Duty Stand

This versatile option accommodates various hammock sizes while maintaining exceptional load capacity.

Key Features:

* Weight capacity: 500 lbs (227 kg)

* Material: Powder-coated steel frame with reinforced stress points

* Adjustable length: 10-14 feet (3-4.3 m)

* Multiple hanging points for perfect tension adjustment

* Includes ground anchors for additional stability

* Tool-free assembly and adjustment

Best For: Users with multiple hammocks of different sizes requiring one versatile solution.

| Stand Model | Weight Capacity | Length | Material | Best Feature | Price Range |

|---|---|---|---|---|---|

| Steel Frame H-Base XL | 600 lbs (272 kg) | 15 ft (4.6 m) | Powder-coated steel | Maximum stability | $$$$ |

| Portable Heavy-Duty | 550 lbs (249 kg) | 9.5 ft (2.9 m) | Galvanized steel | Portability | $$$ |

| Modern Curved Wood | 500 lbs (227 kg) | 15 ft (4.6 m) | Laminated cypress | Aesthetics | $$$$ |

| All-Weather Stainless | 650 lbs (295 kg) | 12 ft (3.7 m) | 316 stainless steel | Durability | $$$$$ |

| Adjustable XL | 500 lbs (227 kg) | 10-14 ft (3-4.3 m) | Powder-coated steel | Versatility | $$$ |

For those specifically seeking portable options with substantial weight capacity, our collection of portable hammocks stands includes models designed for both convenience and strength.

A-Frame Stand Hammock Sets, Swinging Hammock Chair Sets

$154.62 Select options This product has multiple variants. The options may be chosen on the product pageClassic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

$286.31 Select options This product has multiple variants. The options may be chosen on the product pageDouble / Two Person Hammock Sets, Rope Hammock Sets

Double Traditional Cotton Rope Hammock with Extension Chains – 450 lbs Capacity for Backyard & Patio$292.98 Select options This product has multiple variants. The options may be chosen on the product pageFolding Hammock Sets, Quick Setup Hammock Sets

Price range: $305.52 through $583.27 Select options This product has multiple variants. The options may be chosen on the product pageHeavy Duty Hammock Sets, Wooden Arc Stand Hammock Sets

$878.66 Select options This product has multiple variants. The options may be chosen on the product page

Installation and Setup for Maximum Stability

Proper assembly is crucial for any hammock stand to achieve its full weight capacity and stability potential. Even the strongest stand can become unsafe if incorrectly assembled.

Essential Assembly Steps:

1. Clear a level area larger than the stand’s footprint

2. Organize all components and verify all parts are included

3. Begin with the base assembly, ensuring it’s square and level

4. Tighten all connections firmly but don’t over-tighten (can damage threads)

5. Install support components in the sequence specified by manufacturer

6. Add hammock attachment points last after verifying overall stability

7. Test the stand with gradual weight before full use

Critical Connection Points:

* Pay special attention to joints where weight forces concentrate

* Ensure all bolts have lock washers or locking nuts to prevent loosening

* Check that all pre-welded joints show no signs of cracks or weakness

* Verify that feet make full contact with the ground surface

Surface preparation significantly impacts stability. For outdoor installation, avoid soft soil that can allow sinking under weight. For indoor use, provide floor protection while ensuring the stand doesn’t slide on smooth surfaces.

Before applying full weight, conduct a testing protocol:

* Apply 25% of intended weight and check for stability

* Increase to 50% while observing any movement or sounds

* Finally test with full intended weight briefly before extended use

For step-by-step guidance specific to popular stand styles, learning how to set up garden A-frame hammocks provides valuable insights applicable to many heavy-duty models.

Maintenance Practices to Preserve Load-Bearing Integrity

Regular maintenance is essential for preserving the structural integrity and safety of heavy-duty hammock stands. A consistent care routine prevents deterioration that could compromise weight capacity over time.

Inspection Checklist by Frequency:

Before Each Use:

* Visual check of all connection points and hardware

* Verification that feet are stable and level

* Quick assessment of hammock attachment points

Monthly Maintenance:

* Tightening of all bolts and connections

* Inspection for early signs of rust or corrosion

* Cleaning of debris from joints and moving parts

* Verification of stand levelness and stability

Seasonal Care:

* Complete hardware check and replacement of any damaged components

* Application of protective treatments appropriate to the material

* Thorough cleaning of all surfaces

* Structural assessment including load testing

Material-Specific Maintenance:

For steel stands, watch for rust formation at connection points and scratches in protective coatings. Early intervention with touch-up paint or rust converter can prevent structural weakening.

Wooden stands require inspection for cracks, splits, or water damage—particularly at stress points where the hammock attaches. Regular application of sealant (typically annually) preserves structural integrity.

When storing stands during off-seasons, disassemble if practical and store components in dry conditions. Even “all-weather” stands benefit from protection during extended non-use periods.

Warning signs that indicate compromised structural integrity include:

* Unusual creaking or popping sounds during use

* Visible bending or deformation of frame components

* Excessive movement or wobbling under normal weight

* Rust penetration beyond surface level

Comprehensive indoor outdoor hammock safety guidelines provide additional maintenance protocols to ensure your entire hammock system remains safe over time.

DIY Options: Building a Heavy-Duty Hammock Stand

For those with woodworking or metalworking skills, creating a custom heavy-duty hammock stand can be a rewarding project that delivers precisely the specifications needed for your large hammock.

Material Considerations for DIY Heavy-Duty Stands:

* Pressure-treated 4×6 lumber for wooden designs

* Schedule 40 steel pipe (1.5-2 inch diameter) for metal constructions

* Galvanized steel fittings and hardware throughout

* Marine-grade bolts and connectors (minimum 3/8-inch diameter)

Design Principles for Safety:

* Apply a minimum 2.5× safety factor to all weight calculations

* Incorporate triangular support structures wherever possible

* Design base width at least 60% of the stand height

* Include diagonal bracing to prevent lateral movement

* Plan for ground anchoring options from the beginning

Basic Tool Requirements:

* Circular saw or miter saw for wooden stands

* Metal cutting tools and welding equipment for steel designs

* Drill with appropriate bit sizes for hardware

* Measuring tools and levels for precise alignment

* Wrenches and sockets for secure assembly

A typical DIY heavy-duty wooden stand can cost $150-300 in materials compared to $400-700 for commercial options of similar capacity. Metal DIY stands typically range from $200-400 in materials depending on design complexity and hardware quality.

Before using any DIY stand, implement a thorough testing protocol:

1. Begin with static weight testing at 25% of designed capacity

2. Gradually increase to 50%, observing for any movement or sounds

3. Test with full designed weight briefly before extended use

4. Recheck all components after initial loading

Safety Tips and Best Practices for High-Capacity Hammock Stands

Maximizing safety with heavy-duty hammock stands requires ongoing attention to proper use and maintenance. These practices help ensure your relaxation remains worry-free.

1. Respect Weight Limits Absolutely

* Never exceed the manufacturer’s stated capacity

* Remember to include the weight of all users plus the hammock itself

* Be especially cautious with dynamic movements like swinging or bouncing

2. Practice Proper Weight Distribution

* Position yourself in the center of the hammock

* For two-person use, balance weight evenly from end to end

* Enter and exit from the center rather than the sides when possible

* Avoid concentrated weight on a single point of the stand

3. Maintain Consistent Inspection Routines

* Check for loose hardware before each use

* Look for developing rust or cracks in structural components

* Verify that feet remain level and stable on their surface

* Inspect hammock attachment points for wear

4. Recognize Warning Signs

* Unusual noises (creaking, groaning, or popping)

* Visible bending or distortion in frame components

* Excessive movement or swaying of the stand structure

* Growing rust spots or splitting wood

5. Ensure Proper Placement

* Set up on flat, level ground whenever possible

* Maintain clearance around all sides of the stand

* Keep away from fire pits, grills, or other heat sources

* Avoid placement under dead tree limbs or other falling hazards

For multiple users, extra caution is warranted—coordinate entry and exit from the hammock rather than moving independently, which can create unpredictable force distribution.

Finding the right location for your heavy-duty setup is crucial for both safety and enjoyment. Our guide to perfect hammock placement helps identify ideal spots that combine comfort with proper support conditions.

FAQs About Heavy-Duty Hammock Stands

How can I tell if a hammock stand is truly “heavy-duty”?

Look beyond marketing terms to specific indicators: weight capacity of at least 450 lbs (204 kg), material thickness (12-14 gauge steel or equivalent), reinforced connection points, and wide-stance bases. Quality heavy-duty stands also typically weigh more than standard models, reflecting their more substantial construction.

Can I use any large hammock with a heavy-duty stand?

Not necessarily. While the stand may support the weight, dimensional compatibility is equally important. Verify that your hammock length matches the recommended range for the stand—typically 2 feet longer than the stand itself. Also check attachment methods, as Brazilian-style hammocks require different connection points than spreader-bar models.

Are portable heavy-duty stands as strong as stationary ones?

The best portable heavy-duty stands can approach the strength of permanent models, typically supporting 450-550 lbs versus 600-800+ lbs for stationary versions. The trade-off comes in stability—portable stands generally have narrower bases and may require more careful weight distribution.

Can heavy-duty hammock stands be used indoors?

Yes, many heavy-duty stands work well indoors, but consider these factors: ensure floor protection for heavy steel stands, verify ceiling clearance for taller models, and choose designs with non-marking feet. Indoor placement requires the same stability considerations as outdoor use, particularly on smooth flooring where sliding is possible.

How difficult is assembly for typical heavy-duty stands?

Most quality heavy-duty stands require moderate assembly (30-60 minutes) with basic tools. Steel stands typically involve connecting pre-formed tubes with included hardware, while wooden stands may come partially assembled with final connections needed. Some premium models feature tool-free designs with quick-connect components despite their heavy-duty nature.

What should I expect regarding warranties for weight capacity claims?

Quality manufacturers typically offer 1-3 year warranties covering structural failure under normal use within the stated weight capacity. Premium models may offer 5+ year or lifetime structural warranties. Be wary of stands with very limited warranties (less than 1 year) or those that specifically exclude weight-bearing components from coverage.

Can heavy-duty stands be left outside year-round?

Weather-resistant heavy-duty stands can generally withstand year-round exposure, though their lifespan will be maximized with some protection. Steel stands with quality powder coating or galvanization and wooden stands with proper sealing can last many years outdoors. However, in extreme climates (coastal salt air, heavy snow regions), seasonal storage or covers will significantly extend service life.

Finding the perfect location for your heavy-duty hammock setup combines technical considerations with personal preferences. Our guide to best indoor outdoor hammock locations provides extensive guidance on creating the ideal environment for your relaxation system.