1. Introduction: Why Material Choice is Critical for Heavy-Duty Stands

When it comes to heavy-duty stands, the materials used in construction make all the difference between a reliable, long-lasting product and one that fails when you need it most. Heavy-duty stands are those specifically designed to support substantial weight—typically 300+ pounds (136+ kg) or more—while maintaining stability and safety over time.

The materials you select determine not just how much weight your stand can hold, but also:

- How long the stand will last under regular use

- Whether it will resist rusting, corrosion, or environmental damage

- If it’s stable enough to prevent accidents or tipping

- How portable or permanent the installation will be

- The overall value considering initial cost versus lifespan

Making an informed decision about stand materials isn’t just about aesthetics—it’s a safety consideration that directly impacts performance. Imagine setting up a hammock stand that collapses under weight because the materials weren’t strong enough, or installing an outdoor equipment stand that rusts through after one rainy season.

In this guide, we’ll explore the main material categories for heavy-duty stands:

– Various steel alloys (carbon steel, alloy steel, stainless steel)

– Aluminum alloys

– Cast iron

– Engineered polymers and composites

– Wood and hybrid materials

By understanding the strengths and limitations of each material option, you’ll be equipped to select the right material for your specific needs—whether you’re choosing a hammock installation with proper safety considerations or selecting from heavy-duty hammock sets that will provide years of reliable use.

2. Understanding Critical Material Properties for Heavy-Duty Applications

Before diving into specific materials, it’s important to understand the key properties that determine how well a material will perform in heavy-duty applications. These properties serve as the foundation for evaluating which material is right for your needs.

Strength Metrics

- Tensile Strength: How much pulling force a material can withstand before breaking. Think of this as how well a hammock stand resists being pulled apart when weight is applied.

- Yield Strength: The point at which a material begins to deform permanently. This determines when your stand stops bouncing back and starts bending permanently.

- Compressive Strength: How much pushing or squeezing force a material can handle—crucial for stand legs and support points.

Durability Indicators

- Fatigue Resistance: How well the material handles repeated stress cycles without failing. This matters for stands that will see frequent use or loading/unloading.

- Wear Resistance: The material’s ability to resist surface damage from friction or impact.

Stability Factors

- Stiffness: Resistance to bending or flexing under load. Higher stiffness means less wobble in your stand.

- Vibration Dampening: How effectively the material absorbs vibrations rather than transmitting them.

Environmental Resistance

- Corrosion Resistance: Ability to withstand rust, oxidation, and chemical damage.

- UV Stability: Resistance to breaking down or weakening from sun exposure.

- Temperature Tolerance: Performance across hot and cold conditions without compromising strength.

Practical Considerations

- Weight-to-Strength Ratio: How light or heavy the material is relative to its strength.

- Cost-Effectiveness: Initial purchase price balanced against expected lifespan.

- Fabrication Requirements: How easily the material can be shaped, welded, or connected.

Understanding these properties helps when considering hammock weight capacity guidelines and determining if your stand material will perform as needed. Similarly, these factors directly impact whether certain materials are suitable for stands that will be left outside for extended periods.

3. Steel Alloys: The Backbone of Heavy-Duty Support

When absolute strength and reliability are priorities, steel alloys remain the gold standard for heavy-duty stands. Let’s examine the main types and their unique characteristics.

Carbon Steel (A36, 1018)

Carbon steel is the workhorse of heavy-duty stand materials, offering exceptional strength at an affordable price point.

Properties and Characteristics:

– Excellent tensile strength (typically 50,000-80,000 PSI or 345-550 MPa)

– Superior load-bearing capacity for standard tubing dimensions

– Readily available in various shapes and sizes

– Relatively easy to fabricate, weld, and modify

Pros:

– Very cost-effective compared to other high-strength options

– Absorbs vibration better than aluminum

– Can handle significant impact without permanent damage

– Easily repaired if damaged

Cons:

– Heavy weight makes mobility challenging

– Highly susceptible to rust and corrosion without proper treatment

– Requires protective coating for outdoor use

Ideal Applications:

– Permanent outdoor hammock stands

– Workshop equipment stands requiring maximum stability

– Industrial applications where weight isn’t a concern

Alloy Steel (4130 Chromoly, HSLA)

Alloy steels incorporate additional elements to enhance specific properties while maintaining steel’s fundamental strength.

Properties and Characteristics:

– Higher strength-to-weight ratio than standard carbon steel

– Enhanced fatigue resistance for cyclic loading

– Better performance in extreme temperatures

– Superior weldability while maintaining strength

Pros:

– Up to 20-30% weight reduction compared to carbon steel for equivalent strength

– Better resistance to fatigue failure

– More responsive to heat treatment for custom properties

– Generally more durable in dynamic loading situations

Cons:

– Higher cost than standard carbon steel

– Still requires corrosion protection

– Less readily available in standard sizes

Ideal Applications:

– Premium portable stands where weight matters but strength can’t be compromised

– High-stress applications with frequent loading/unloading cycles

– Stands subject to vibration or movement

Stainless Steel (304, 316)

Stainless steel offers superior corrosion resistance while maintaining excellent strength properties.

Properties and Characteristics:

– Built-in corrosion resistance without additional treatments

– Clean, modern aesthetic appearance

– Available in various finishes (brushed, polished)

– Maintains strength in extreme environments

Pros:

– Exceptional corrosion resistance, even in marine environments

– No need for protective coatings

– Maintains appearance over time with minimal maintenance

– Hygienic surface that’s easy to clean

Cons:

– Significantly more expensive than carbon steel (2-5 times higher)

– Slightly lower strength than some carbon steels

– More challenging to weld properly

– Heavier than aluminum alternatives

Ideal Applications:

– Marine or beachfront hammock stands

– Pool area or water-adjacent installations

– High-end visible applications where aesthetics matter

– Medical or food-adjacent equipment stands

Steel stands dominate the market for hammock chairs and stands where stability and reliability are paramount. The choice between steel types often comes down to environmental exposure, budget constraints, and whether the stand needs to be moved regularly or will remain in a fixed location.

4. Aluminum Alloys: When Weight and Corrosion Resistance Matter

Aluminum alloys have revolutionized the heavy-duty stand market by offering a compelling alternative when portability is crucial without sacrificing too much strength.

Key Aluminum Alloys for Structural Applications

6061-T6 Aluminum:

– The most common structural aluminum alloy

– Good balance of strength, corrosion resistance, and weldability

– Tensile strength around 45,000 PSI (310 MPa)—about 60% of standard steel

– Excellent formability and machinability

7075 Aluminum:

– Premium high-strength alloy approaching steel’s strength

– Tensile strength up to 83,000 PSI (572 MPa)

– Less commonly used in stands due to higher cost

– More difficult to weld but exceptional for mechanically fastened components

Strength-to-Weight Advantage

Aluminum’s defining characteristic is its impressive strength-to-weight ratio:

– Approximately 1/3 the weight of steel

– A 1-inch aluminum tube can replace a steel tube with only a modest increase in diameter

– Makes one-person setup possible for otherwise heavy-duty applications

– Enables truly portable heavy-duty stands

Corrosion Resistance

Unlike steel, aluminum naturally forms a protective oxide layer:

– No rusting, even in humid or wet environments

– Performs well in outdoor settings without additional treatments

– Surface oxidation actually protects the material beneath

– Can develop chalky residue over time but structural integrity remains

Surface Treatments

To enhance aluminum’s natural properties:

– Anodizing: Creates harder, more wear-resistant surface with decorative color options

– Powder Coating: Adds color while improving scratch and chip resistance

– Clear Coating: Preserves metallic appearance while adding protection

Limitations

Aluminum isn’t without drawbacks:

– More prone to bending (deflection) under load compared to steel

– More susceptible to fatigue failure with repeated loading

– Can be more expensive than basic carbon steel

– Requires different design approaches to achieve equivalent rigidity

Aluminum stands are particularly well-suited for portable hammocks and stands where users need to move or store the stand regularly. They’re also popular choices for lightweight hammock sets that balance durability with ease of handling.

5. Cast Iron: Traditional Stability for Static Loads

Cast iron stands apart from other materials with a unique set of properties that make it ideal for specific heavy-duty applications, particularly those requiring maximum stability.

Unique Properties of Cast Iron

Cast iron is characterized by its high carbon content (2-4%), which creates a material with:

– Exceptional compressive strength

– Natural vibration dampening capabilities

– Superior stability due to substantial weight

– High thermal mass that resists temperature fluctuations

Vibration Dampening Excellence

One of cast iron’s standout qualities is its ability to absorb vibration:

– Up to 10 times better at dampening vibrations than steel

– Absorbs sound and reduces resonance

– Provides rock-solid stability for sensitive equipment

– Creates a “dead blow” effect that reduces bounce

Design Considerations

Cast iron has specific characteristics that affect how it’s used:

– Typically formed through casting rather than welding or bending

– Allows complex shapes with uniform strength

– Works well for bases and support components

– Often combined with other materials in hybrid designs

Pros:

- Unmatched stability for stationary applications

- Superior vibration control

- Excellent durability in protected environments

- Often recyclable from existing components

- Classic, timeless aesthetic appeal

Cons:

- Extremely heavy and difficult to transport

- Brittle nature makes it vulnerable to cracking if dropped

- Limited tensile strength compared to steel

- Poor corrosion resistance without proper treatment

- Not suitable for portable applications

While cast iron isn’t commonly used for portable hammock stands, its properties make it excellent for permanent installations. Understanding material options becomes particularly important when deciding between indoor versus outdoor hammocks, as the environment directly impacts which material will perform best over time.

6. Engineered Polymers and Composites: Modern Alternatives

As material science advances, engineered polymers and composites have emerged as viable alternatives to traditional metals for certain heavy-duty applications. These materials offer unique benefits that metals simply can’t match.

High-Density Polyethylene (HDPE) and Reinforced Plastics

HDPE and reinforced plastic materials have carved out their own niche in stand applications:

Key Properties:

– Completely immune to rust and corrosion

– Naturally waterproof with excellent UV resistance

– Lightweight compared to equivalent metal options

– Available in various colors without requiring coating

– Will not splinter like wood or conduct electricity like metal

Ideal Applications:

– Marine environments where metal corrosion is problematic

– Chemical exposure settings where reactivity is a concern

– Outdoor furniture stands exposed to harsh elements

– Applications requiring electrical insulation

– Situations where weight must be minimized

Limitations:

– Lower overall strength compared to metals

– Greater thickness required for equivalent support

– More prone to deformation under sustained loading

– May degrade from certain chemical exposures

– Often more expensive than basic steel options

Fiberglass (FRP) and Composite Materials

Fiberglass and other composite materials offer an excellent middle ground between metals and plastics:

Key Properties:

– Exceptional corrosion resistance even in extreme environments

– Non-conductive for electrical applications

– High strength-to-weight ratio

– Can be molded into complex shapes

– Available in various colors and finishes

Ideal Applications:

– Corrosive environments (chemical plants, water treatment)

– Electrical isolation requirements

– Lightweight structural components

– Custom-shaped stand components

Limitations:

– Higher cost than standard metal options

– Specialized fabrication requirements

– Less commonly available in standard profiles

– Can be damaged by UV exposure without proper formulation

Carbon Fiber Composites

At the premium end of the spectrum, carbon fiber offers unmatched performance:

Key Properties:

– Extraordinary strength-to-weight ratio (stronger than steel at 1/5 the weight)

– Exceptional fatigue resistance

– Zero corrosion concerns

– Professional, high-tech appearance

– Remarkable stiffness with minimal weight

Ideal Applications:

– Ultra-lightweight premium portable stands

– High-end visible applications

– Maximum performance with minimum weight

– Applications where cost is secondary to performance

Limitations:

– Significantly higher cost than other materials

– Specialized fabrication and repair requirements

– Can be brittle if improperly designed

– Difficult to modify after production

When creating the perfect hammock haven, these modern materials offer distinctive benefits for specific environments where traditional materials might struggle. The choice between traditional and modern materials often comes down to the specific performance requirements and environmental conditions.

7. Wood and Hybrid Materials: Traditional Solutions in Modern Context

Despite advances in synthetic and metal materials, wood remains a relevant and effective option for many heavy-duty stand applications, particularly when aesthetics and natural feel are priorities.

Hardwood Varieties for Heavy-Duty Applications

Not all wood is suitable for supporting significant weight. The best hardwood options include:

White Oak:

– Exceptional strength and durability

– Natural resistance to rot and moisture

– Beautiful grain pattern

– Long history in structural applications

Maple:

– Extremely hard and dense

– Resistant to wear and abrasion

– Clean appearance with subtle grain

– Excellent stability when properly dried

Ash:

– Outstanding strength-to-weight ratio

– Excellent shock resistance

– Attractive grain similar to oak

– Traditional material for tool handles due to strength

Ipe and Exotic Hardwoods:

– Extraordinary density and hardness

– Natural oils resist insects and decay

– Can last decades even in outdoor settings

– Minimal maintenance requirements

Engineered Wood Products

Modern wood technology has created improved options:

– Laminated Veneer Lumber (LVL): Engineered to eliminate natural defects

– Cross-Laminated Timber: Enhanced stability by alternating grain direction

– Glulam Beams: Allow for larger dimensions than natural timber

Natural Benefits of Wood

Wood brings unique advantages to stand applications:

– Natural vibration dampening reduces movement and noise

– Warm aesthetic that blends with home decor

– Can be easily customized, shaped, and finished

– Renewable resource with lower environmental impact

– Gets stronger as it dries and ages (unlike many synthetics)

Limitations and Solutions

Wood’s natural vulnerabilities can be addressed:

– Susceptibility to moisture can be mitigated with proper sealing

– UV damage prevented with regular maintenance

– Design can compensate for strength limitations

– Hybrid designs can combine wood’s aesthetics with metal’s strength

Wood remains particularly popular for wooden hammock stands where the natural aesthetic complements outdoor and indoor spaces. Modern treatments and hybrid designs have extended wood’s viability as a heavy-duty material, allowing it to compete with more modern alternatives in many applications.

8. Material Comparison: Choosing the Right Option for Your Application

With so many material options available, making the right selection requires careful consideration of your specific needs. This comparative analysis will help guide your decision-making process.

Comprehensive Comparison Table

| Material | Strength | Weight | Corrosion Resistance | Initial Cost | Lifespan Value | Ease of Fabrication | Aesthetics |

|---|---|---|---|---|---|---|---|

| Carbon Steel | Excellent | Heavy | Poor (needs coating) | Low | Good with maintenance | Excellent | Industrial |

| Alloy Steel | Superior | Moderate-Heavy | Poor (needs coating) | Moderate | Excellent | Good | Industrial |

| Stainless Steel | Very Good | Heavy | Excellent | High | Excellent | Moderate | Premium |

| Aluminum | Good | Light | Very Good | Moderate | Good | Good | Modern |

| Cast Iron | Good (compressive) | Very Heavy | Fair | Moderate | Excellent | Poor (casting only) | Traditional |

| HDPE/Plastics | Fair | Very Light | Excellent | Moderate | Good | Poor | Casual |

| Fiberglass/Composites | Good | Light | Excellent | High | Very Good | Poor | Technical |

| Carbon Fiber | Excellent | Ultra-Light | Excellent | Very High | Good | Poor | Premium Technical |

| Hardwood | Good | Moderate | Fair (needs treatment) | Moderate | Good with care | Good | Natural/Warm |

Selection Based on Load Requirements

When considering how much weight your stand needs to support:

For Maximum Load Capacity (500+ lbs/227+ kg):

– Carbon or alloy steel is typically the most cost-effective solution

– Thicker aluminum sections can work but at higher cost

– Hardwood can be suitable with proper design and species selection

For Moderate Loads (250-500 lbs/113-227 kg):

– Standard aluminum becomes more viable

– Steel remains excellent but may be overbuilt

– Quality hardwood works well with proper design

– Fiberglass becomes competitive for certain applications

For Lighter Loads (Under 250 lbs/113 kg):

– Most materials become viable

– Material selection can prioritize other factors like weight or aesthetics

– Cost-effectiveness may favor aluminum or treated wood

Mobility vs. Stability Considerations

For stands that need to be moved regularly:

– Aluminum offers the best balance of strength and portability

– Carbon fiber is premium but extremely portable

– Plastics work for lighter-duty portable applications

For permanent installations:

– Steel provides excellent stability and value

– Cast iron offers unmatched vibration control

– Hardwood provides natural beauty with good stability

Environmental Exposure Factors

When selecting materials for outdoor use, consider:

– Stainless steel for coastal or high-moisture environments

– Aluminum for good weather resistance with less weight

– Treated hardwoods for natural aesthetic with good durability

– HDPE for complete weather immunity with moderate strength

The material you select should align with where you plan to place your stand. The best indoor and outdoor hammock locations will influence which material properties are most important for your specific situation.

9. Application-Specific Material Recommendations

Different applications have unique requirements that make certain materials more suitable than others. Here are specific recommendations for common heavy-duty stand uses.

Industrial Machinery Stands

Industrial environments demand materials that prioritize safety, stability, and durability:

Primary Recommendation: Carbon or Alloy Steel

– Provides necessary strength for heavy machinery

– Handles vibration without fatigue failure

– Cost-effective for the performance required

– Can be easily modified or reinforced as needed

Secondary Options:

– Cast iron bases for vibration-sensitive equipment

– Stainless steel for washdown areas or chemical exposure

– Aluminum for lighter-duty applications requiring mobility

Design Considerations:

– Incorporate leveling feet to manage uneven floors

– Include additional bracing for dynamic loads

– Consider welded construction for maximum rigidity

– Powder coating provides better durability than paint

Automotive and Workshop Stands

In garage and workshop environments, stands need to balance safety with usability:

Primary Recommendation: Carbon Steel

– Strong enough for safety-critical applications

– Cost-effective for the typical DIY user

– Can withstand occasional impacts

– Easily repaired if damaged

Secondary Options:

– Aluminum for portable jacks and lightweight stands

– Hardwood for custom workbenches with integrated stands

– Hybrid designs combining wood tops with metal bases

Key Considerations:

– Powder coating provides best resistance to shop chemicals

– Floor contact points should be reinforced

– Include safety features like positive locking mechanisms

– Consider folding designs for space-constrained shops

Display and Retail Stands

Commercial display stands must balance aesthetics with functional requirements:

Primary Recommendation: Aluminum or Stainless Steel

– Professional appearance suitable for customer-facing areas

– Good strength-to-weight ratio for movable displays

– Corrosion resistance ensures long-term appearance

Secondary Options:

– Hardwood for upscale retail environments

– Carbon fiber for ultra-premium displays

– Powder-coated steel for budget-conscious applications

Design Factors:

– Hidden fasteners for clean appearance

– Modular design to allow reconfiguration

– Consider integrated cable management

– Weight distribution for stability with minimal footprint

Outdoor and Corrosive Environment Stands

Stands exposed to the elements require special material considerations:

Primary Recommendation: Stainless Steel or Aluminum

– Natural corrosion resistance without additional treatments

– Maintains appearance and structural integrity over time

– Minimal maintenance requirements

Secondary Options:

– HDPE for complete weather immunity

– Specialized treated hardwoods (teak, ipe)

– Hot-dipped galvanized steel for budget applications

Key Considerations:

– Drainage features to prevent water accumulation

– UV-resistant materials for sun exposure

– Marine-grade options for saltwater proximity

– Hardware that matches material corrosion resistance

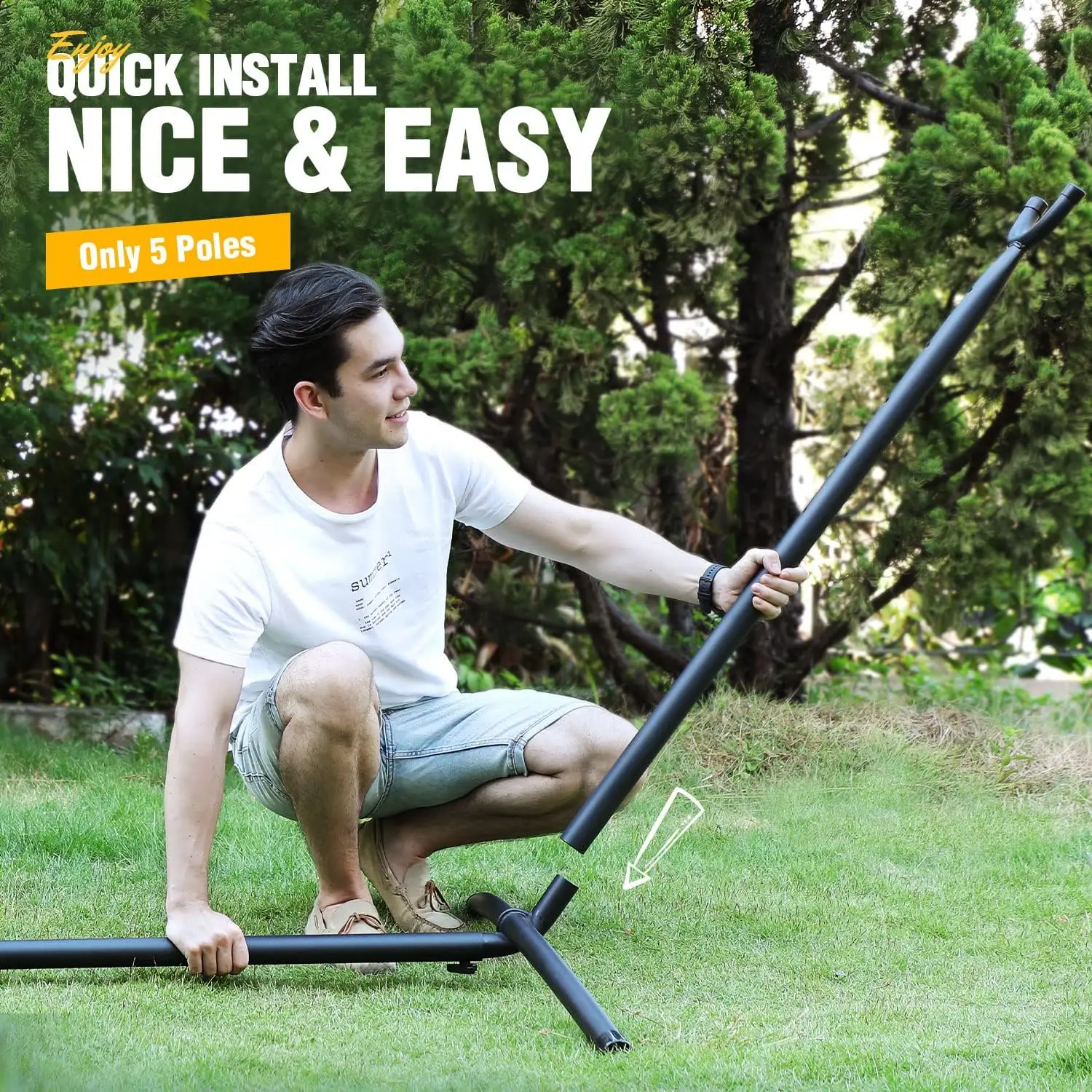

Portable and Collapsible Stands

For stands that need to be regularly moved or stored:

Primary Recommendation: Aluminum Alloys

– Excellent strength-to-weight ratio

– Naturally corrosion resistant

– Available in various structural profiles

– Good balance of cost and performance

Secondary Options:

– Carbon fiber for premium ultralight applications

– Steel-aluminum hybrids for critical load points

– Reinforced engineered polymers for specific applications

Design Considerations:

– Intuitive assembly/disassembly without tools

– Compact folded footprint for storage

– Reinforced connection points that withstand repeated use

– Carry bags or integrated handles for transportation

A-frame stand hammock sets and double two-person hammock sets require particularly robust materials to handle the increased loads and forces. The material selection directly impacts both the safety and user experience.

Dark Wood Hammock Sets, Porch Swing Chair Sets

$653.82 Select options This product has multiple variants. The options may be chosen on the product pageA-Frame Stand Hammock Sets, Swinging Hammock Chair Sets

$154.62 Select options This product has multiple variants. The options may be chosen on the product pageCamping Hammock Sets with Bug Net, Ultralight Camping Hammock Sets

$139.72 Select options This product has multiple variants. The options may be chosen on the product pageLight Wood Hammock Sets, Swinging Hammock Chair Sets

$1,359.35 Select options This product has multiple variants. The options may be chosen on the product pageClassic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

$286.31 Select options This product has multiple variants. The options may be chosen on the product page

10. Design Factors That Enhance Material Performance

Even the best materials can underperform if not properly designed. Conversely, thoughtful design can maximize the effectiveness of more affordable materials.

Structural Design Principles

The way a stand is engineered can significantly impact its performance:

Cross-Bracing and Triangulation:

– Triangular structures distribute forces more effectively

– Diagonal bracing prevents parallelogram deformation

– Proper triangulation can double effective strength with minimal weight

Material Profile Selection:

– Tubular profiles offer superior strength-to-weight than solid stock

– I-beams and U-channels provide directional strength

– Box sections offer balanced strength in multiple directions

Wall Thickness Optimization:

– Strategic thickness increases at stress points

– Uniform thickness for materials prone to stress concentration

– Tapered designs that put material where it’s most needed

Joining Methods Impact

How components connect directly affects overall performance:

Welding Considerations:

– Full penetration welds for maximum strength

– Proper heat treatment post-welding for alloy steels

– Appropriate welding methods for specific materials (TIG for aluminum)

Mechanical Fastening:

– Bolted connections allow disassembly but create stress points

– Distributed fastener patterns prevent localized failure

– Lock washers and thread-locking compounds prevent loosening

Hybrid Connection Approaches:

– Weld critical structural elements

– Use mechanical fasteners for adjustable or removable components

– Consider adhesives for certain materials (composites)

Load Distribution Principles

How force travels through a stand is just as important as the material itself:

Distributed Loading:

– Wider contact areas reduce point loading

– Gradual transitions avoid stress concentration

– Load-spreading design elements extend material life

Foundation and Mounting:

– Leveling mechanisms compensate for uneven surfaces

– Wide feet distribute weight across more floor area

– Anchoring options for permanent installations

The success of any stand installation depends not just on material quality but on proper placement and setup. For hammocks specifically, perfect placement in home and garden settings significantly affects the forces applied to the stand and thus the material requirements.

11. Treatments and Coatings: Extending Material Lifespan

The right protective treatments can dramatically extend the useful life of heavy-duty stands while enhancing their appearance and performance.

Steel Protection Options

Hot-Dip Galvanization:

– Molten zinc coating that bonds metallurgically to steel

– Provides 20+ years of corrosion protection in most environments

– Self-healing where minor damage occurs

– Somewhat rough appearance but extremely durable

Powder Coating:

– Electrostatically applied polymer coating baked onto the surface

– Excellent resistance to chips, scratches, and UV damage

– Wide range of color and texture options

– Typically lasts 15-20 years with proper application

Zinc Plating (Electroplating):

– Thin protective layer suitable for indoor applications

– More economical than hot-dip galvanizing

– Provides 5-10 years of protection in non-harsh environments

– Smooth finish with silver-blue appearance

Paint Systems:

– Economical but less durable than powder coating

– Requires proper surface preparation and primer

– Easy to touch up when damaged

– Typically offers 5-7 years of protection

Aluminum Treatments

Anodizing:

– Electrochemical process that enhances natural oxide layer

– Creates harder surface more resistant to wear

– Can be dyed various colors during the process

– Excellent corrosion resistance without changing dimensions

Powder Coating:

– Similar benefits to steel powder coating

– Requires special preparation for proper adhesion

– Provides color options beyond anodizing

– More chip-resistant than anodized finishes

Clear Coating:

– Preserves metallic appearance

– Less durable than anodizing but maintains natural look

– Good for decorative indoor applications

– Can be reapplied when worn

Wood Protection

Exterior-Grade Sealants:

– Polyurethane or marine varnish for maximum water resistance

– UV inhibitors prevent sun damage and graying

– Requires reapplication every 1-3 years depending on exposure

– Maintains wood’s natural beauty while protecting

Penetrating Oils:

– Linseed, tung, or specialized deck oils

– Penetrate wood fibers rather than creating surface film

– Easier to maintain without stripping

– May require more frequent reapplication

Pressure Treatment:

– Chemical infusion providing long-term rot and insect resistance

– Suitable for ground contact applications

– Can last decades with minimal maintenance

– Limited to certain wood species

Properly treating and maintaining your stand materials directly impacts safety. For indoor applications especially, understanding indoor outdoor hammock safety guides can help determine the appropriate treatment level needed to maintain material integrity over time.

12. Maintenance Practices for Different Stand Materials

Each material requires specific maintenance approaches to maximize lifespan and ensure continued safety.

Steel Maintenance Protocol

Regular Inspection Points:

– Check for rust formation, especially at joints and welds

– Look for paint bubbling indicating corrosion underneath

– Examine weld integrity for cracks or separation

– Inspect hardware for loosening or corrosion

Cleaning Recommendations:

– Clean with mild soap and water to remove contaminants

– Avoid abrasive cleaners that damage protective coatings

– Dry thoroughly after cleaning to prevent moisture trapping

– Apply automotive wax to powder-coated surfaces for added protection

Preventative Measures:

– Touch up damaged paint or coating promptly

– Apply rust converter to any developing rust spots

– Keep indoor/outdoor transition pieces dry between uses

– Use furniture covers for seasonal protection

Aluminum Maintenance

Inspection Focus Areas:

– Check for galvanic corrosion where aluminum meets other metals

– Examine mechanical fasteners for proper tension

– Look for stress cracks at load-bearing points

– Verify that anodized surfaces haven’t been damaged

Cleaning Best Practices:

– Use non-alkaline cleaners (aluminum reacts with alkaline solutions)

– Avoid abrasive materials that scratch protective coatings

– Rinse thoroughly to remove cleaning compounds

– Apply automotive wax to painted aluminum for additional protection

Preventative Care:

– Isolate from dissimilar metals using nylon washers

– Keep moving connections lubricated with silicone-based products

– Protect from highly acidic or alkaline substances

– Consider periodic re-anodizing for high-wear components

Wood Maintenance

Critical Inspection Items:

– Check for water damage, softening, or discoloration

– Examine for cracking or splitting, especially near hardware

– Look for insect activity or damage

– Test for structural integrity near ground contact points

Cleaning Approach:

– Clean with specialized wood cleaners appropriate for finish type

– Remove mold or mildew immediately with appropriate solutions

– Allow to dry thoroughly before applying treatments

– Sand lightly between finish applications when refinishing

Preventative Care:

– Reapply finishes before failure occurs

– Keep wood stands on protective feet to prevent ground contact

– Store indoors during harsh weather if possible

– Address minor damage before it spreads

Composite and Polymer Maintenance

Inspection Points:

– Look for UV degradation (chalking, color change)

– Check for stress whitening at load points

– Examine for cracks or delamination

– Verify fastener integrity as plastics can creep over time

Cleaning Guidelines:

– Use mild soap and water for regular cleaning

– Avoid petroleum-based cleaners on many plastics

– Remove stains with specialized plastic cleaners

– Rinse thoroughly to prevent residue buildup

Preventative Steps:

– Apply UV protectant to extend outdoor life

– Keep away from high heat sources

– Distribute loads evenly to prevent deformation

– Replace before structural integrity is compromised

Understanding the specific maintenance needs of your stand materials is particularly important for indoor applications. When hanging hammocks indoors, proper material maintenance ensures continued safety and performance.

13. Safety Standards and Certifications for Heavy-Duty Stands

Safety should always be the primary consideration when selecting materials for heavy-duty stands. Understanding relevant standards and certifications helps ensure your stand meets appropriate safety requirements.

Key Industry Standards

Different applications have specific standards governing material selection and performance:

ASTM International Standards:

– ASTM A36/A36M: Standard specification for carbon structural steel

– ASTM B221: Standard specification for aluminum alloy extruded bars, rods, wire, profiles

– ASTM F1575: Standard test methods for determining load capacity of furniture

ISO Standards:

– ISO 9001: Quality management systems for manufacturing

– ISO 14001: Environmental management standards affecting material selection

– ISO 8611: Materials and design for load-bearing platforms

Application-Specific Standards:

– Medical equipment stands: FDA guidelines and IEC 60601

– Retail display stands: UL standards for stability and fire resistance

– Construction-related stands: Local building codes and regulations

Material Testing and Verification

Understanding how materials are tested provides insight into their reliability:

Common Testing Protocols:

– Load capacity testing (static and dynamic)

– Accelerated aging for environmental resistance

– Impact resistance for sudden loading

– Cyclic loading for fatigue resistance

Verification Methods:

– Material certification documentation

– Mill test reports for metal alloys

– Third-party testing verification

– Manufacturer conformance declarations

Safety Rating Considerations

When evaluating safety ratings, consider these factors:

Working Load vs. Breaking Strength:

– Working load typically 1/4 to 1/5 of breaking strength

– Safety factors vary by application risk level

– Dynamic loads require higher safety factors than static loads

Environmental Factors Affecting Ratings:

– Temperature extremes can reduce rated capacity

– UV exposure degrades some materials over time

– Chemical exposure may void standard ratings

– Humidity and moisture can affect wood and certain metals

Understanding these safety standards is particularly important for specialized applications like camping hammock stands, which must be both portable and structurally sound under varied conditions.

14. Is Stainless Steel Worth the Premium for Your Stand?

Stainless steel commands a significantly higher price than standard carbon steel—typically 3-5 times more expensive. This premium raises an important question: when is the investment justified?

When Stainless Steel Makes Financial Sense

Stainless steel becomes economically viable in these scenarios:

Harsh Environment Applications:

– Marine or beachfront locations with salt spray

– Pool areas with chlorine exposure

– Outdoor installations in high-humidity climates

– Areas with frequent rain or moisture exposure

Lifecycle Cost Advantages:

– Zero maintenance costs over 15+ year lifespan

– No repainting or refinishing required

– Retained value and appearance over time

– No downtime for maintenance or repair

Aesthetic Requirements:

– Visible installations where appearance matters

– Clean, modern design aesthetic required

– Consistent appearance needed over many years

– Applications where coating damage would be problematic

Cost-Effective Alternatives to Full Stainless Construction

Consider these hybrid approaches for cost optimization:

Strategic Use of Stainless Components:

– Use stainless only for critical outdoor-exposed parts

– Apply stainless hardware with coated steel structural elements

– Utilize stainless for ground-contact or water-contact points

Alternative Protection Methods:

– Hot-dip galvanizing provides excellent protection at lower cost

– Marine-grade powder coating offers good protection at 1/3 the cost

– Specialized aluminum alloys offer comparable corrosion resistance

Return on Investment Calculation:

For a typical outdoor stand costing $200 in carbon steel:

– Stainless version might cost $600-800

– Repainting/maintenance for carbon steel could cost $50 every 2-3 years

– After 10+ years, the lifetime costs begin to equalize

– Factor in convenience and appearance retention for complete value assessment

15. Can Aluminum Stands Really Support Heavy Loads?

Many people question whether aluminum—a material they associate with beverage cans—can truly support significant weight in structural applications. The answer is yes, with proper design and alloy selection.

Engineering for Strength

Aluminum can support heavy loads through smart engineering:

Alloy Selection Matters:

– Structural aluminum alloys (6061-T6, 7075) have tensile strengths from 35,000-90,000 PSI

– Heat treatment significantly increases strength (T6 designation)

– Modern alloys perform far better than older aluminum materials

Profile Design Maximizes Strength:

– Tubular profiles provide exceptional strength-to-weight ratio

– Strategic wall thickness increases at stress points

– I-beam and box sections dramatically increase load capacity

– Reinforced connection points distribute loads effectively

Successful Heavy-Duty Applications:

– Aircraft structural components

– Commercial ladders rated for 300+ pounds

– Scaffolding systems for construction

– Professional-grade camera and equipment tripods

Legitimate Limitations

Understanding aluminum’s true limitations helps set appropriate expectations:

Deflection Considerations:

– Aluminum has approximately 1/3 the stiffness of steel

– Requires larger profiles to achieve equivalent rigidity

– Some visible flexing may occur under load even when safely within limits

Connection Points Matter:

– Welded joints must be properly executed to maintain strength

– Mechanical fasteners need proper design to avoid localized stress

– Thread strength lower than steel—requires different fastener approach

For indoor hammock placement, aluminum stands provide an excellent balance of strength and placement flexibility. Understanding the best places to hang hammocks indoors helps determine if aluminum’s properties align with your specific needs.

16. What Are the Environmental Impacts of Different Stand Materials?

As environmental concerns become increasingly important, understanding the sustainability profile of different materials can inform better choices.

Material Sustainability Comparison

Steel Sustainability Profile:

– 100% recyclable with no degradation in quality

– Current steel contains approximately 25% recycled content

– Energy-intensive production (2,300 kWh per ton on average)

– Long lifespan reduces replacement frequency

– Established recycling infrastructure with high recovery rates

Aluminum Environmental Considerations:

– 100% recyclable with minimal quality loss

– Extremely energy-intensive to produce from raw materials

– Uses 95% less energy when recycled versus virgin production

– Lightweight nature reduces transportation emissions

– Modern production increasingly uses renewable energy

Wood Sustainability Factors:

– Renewable resource when properly harvested

– Carbon sequestration during growth phase

– Low embodied energy compared to metals

– Biodegradable at end of useful life

– Certification systems (FSC, PEFC) verify responsible sourcing

Plastic and Composite Environmental Impact:

– Petroleum-based plastics have high environmental footprint

– Recycled plastic options reduce virgin material demand

– Limited recycling options at end of life for many composites

– Very long lifespan for certain formulations

– Newer bio-based options improving sustainability profile

Lifecycle Considerations

The total environmental impact includes the entire lifecycle:

Production Phase:

– Energy consumption during manufacturing

– Water usage in processing

– Mining impact for metal extraction

– Chemical treatments and coatings

Use Phase:

– Durability and replacement frequency

– Maintenance requirements and associated products

– Weight impact on transportation emissions if moved

– Energy efficiency implications for certain applications

End-of-Life:

– Recyclability percentage

– Ease of material separation

– Local recycling infrastructure availability

– Biodegradability or landfill impact

Making environmentally sound choices often means selecting materials that will last the longest for your specific application, reducing the need for replacement and the associated resource consumption.

17. How Do Extreme Temperatures Affect Stand Material Performance?

Temperature fluctuations can dramatically impact material performance, affecting everything from strength to dimensional stability.

Steel Temperature Response

Cold Temperature Effects:

– Increased brittleness below certain temperatures

– Reduced impact resistance in sub-freezing conditions

– Potential for condensation and internal corrosion

– Generally maintains strength until extremely cold (-40°F/-40°C)

High Temperature Effects:

– Begins losing strength above 800°F (427°C)

– Thermal expansion approximately 6.7 μin/in·°F

– Coating systems may fail at high temperatures

– Generally excellent for normal outdoor temperature ranges

Aluminum Temperature Response

Cold Temperature Effects:

– Becomes stronger as temperature decreases

– Excellent performance in extreme cold

– No ductile-to-brittle transition like steel

– Potential for condensation issues in temperature swings

High Temperature Effects:

– Begins losing strength at much lower temperatures than steel

– Noticeable strength reduction above 200°F (93°C)

– Higher thermal expansion (13.1 μin/in·°F) requires design accommodation

– Anodizing unaffected by temperature but coatings may suffer

Wood Temperature Response

Cold Temperature Effects:

– Becomes stiffer and more brittle when cold

– Dimensional changes with humidity fluctuations

– Finish systems may crack in extreme cold

– Generally good performance when kept dry

High Temperature Effects:

– Progressive strength loss starting around 150°F (66°C)

– Accelerated aging and degradation with heat exposure

– Potential for checking and splitting with temperature cycling

– Finish breakdown with UV and heat combination

Plastic and Composite Temperature Response

Cold Temperature Effects:

– Many plastics become brittle at low temperatures

– Some engineered polymers maintain flexibility in cold

– Potential for cracking with impact in cold conditions

– Coefficient of thermal expansion mismatches can stress joints

High Temperature Effects:

– Significant strength reduction at temperatures as low as 120°F (49°C)

– UV exposure combined with heat accelerates degradation

– Visible sagging possible under load in hot conditions

– Material-specific heat deflection temperatures vary widely

Understanding these temperature effects helps in selecting appropriate materials for your climate and usage patterns.

18. What Are the Most Cost-Effective Materials for DIY Heavy-Duty Stands?

For those looking to build their own heavy-duty stands, finding the right balance between cost, performance, and workability is essential.

Budget-Friendly Material Options

Standard Carbon Steel:

– Best overall value for strength-to-cost ratio

– Readily available in various forms at hardware stores

– Square tubing offers excellent DIY-friendly properties

– Can be protected with affordable spray paint or rust preventatives

– Requires basic welding for best results

Pressure-Treated Lumber:

– Excellent outdoor durability at moderate cost

– Easily worked with common woodworking tools

– Available in standardized dimensions

– Simple mechanical fastening (bolts, screws)

– No specialized skills required beyond basic woodworking

Aluminum (Limited Applications):

– Higher initial cost offset by no finishing requirements

– Pre-finished options eliminate coating steps

– Mechanical fastening possible with proper hardware

– Lightweight for easier handling during construction

Tools and Skills Required

Different materials require varying levels of tools and expertise:

Steel Construction Requirements:

– Welding equipment (MIG welder recommended for DIY)

– Metal cutting tools (angle grinder, reciprocating saw, or circular saw with metal blade)

– Drilling equipment for holes

– Finishing supplies (grinder, sandpaper, paint)

– Basic welding skills or willingness to learn

Wood Construction Requirements:

– Standard power tools (drill, circular saw, jigsaw)

– Measuring and marking tools

– Weather-resistant fasteners and hardware

– Finishing supplies (sandpaper, exterior sealant)

– Basic woodworking knowledge

Cost-Saving Strategies

Maximize value while maintaining safety with these approaches:

Material Sourcing Tips:

– Check metal recyclers for substantial savings on steel

– Look for remnant sections at metal suppliers

– Consider repurposing existing metal items

– Buy in standard lengths to avoid cut charges

Design for Economy:

– Use larger diameter tubing with thinner walls for better value

– Minimize complex joints that require extra material

– Design around standard available dimensions

– Incorporate triangulation to use less material

Finishing Alternatives:

– Consider cold galvanizing spray instead of hot-dip galvanizing

– Explore industrial equipment paint for better durability than standard paint

– Use penetrating deck stain for wood instead of more expensive marine varnish

DIY options can be particularly attractive for quick setup hammock sets where simple, sturdy designs meet functional needs without unnecessary complexity.

19. Conclusion: Making an Informed Material Selection

Selecting the right material for a heavy-duty stand represents a balance between competing factors—strength requirements, environmental conditions, budget constraints, and intended use. By understanding the unique properties and limitations of each material option, you can make choices that optimize performance for your specific needs.

Remember that material selection should always begin with safety considerations. Even the most aesthetically pleasing or cost-effective option is a poor choice if it cannot reliably support the intended load with an appropriate safety margin. Consider not just the immediate loading but how the material will perform over time with repeated use and environmental exposure.

The most successful material selections often involve looking beyond initial cost to consider total lifecycle value. A higher initial investment in premium materials or protective treatments often pays dividends through extended lifespan, reduced maintenance requirements, and better long-term performance.

For specialized applications like hammock stands, material choice directly impacts both safety and user experience. The perfect material balances strength for security with appropriate flex for comfort, while offering the right combination of portability or permanence for your intended use.

By applying the principles and insights from this guide, you can confidently select materials that will provide years of reliable service, whether you’re choosing a pre-manufactured stand or designing your own custom solution.