1. Why Material Selection is Critical for Hammock Stand Safety

When it comes to hammock stands, the material you choose isn’t just about looks—it’s a crucial decision that directly impacts your safety and relaxation experience. The right material provides peace of mind, allowing you to truly unwind without worry about potential collapse or failure.

Material selection affects three critical aspects of any hammock stand:

- Safety: The right material ensures the stand won’t buckle under weight or suddenly fail

- Stability: Strong materials maintain structural integrity even with movement

- Longevity: Durable materials withstand repeated use and environmental stresses

In the context of hammock stands, “strength” specifically refers to a material’s ability to support substantial weight (typically 250-500 pounds), resist bending or warping over time, and maintain structural integrity through repeated use. The consequences of using inadequate materials can range from uncomfortable sagging to dangerous failures—risks that can be easily avoided with informed choices.

Different materials excel in various environments and use cases, which is why understanding indoor and outdoor hammock placement considerations alongside material strength is essential. For those prioritizing maximum strength from the start, exploring heavy-duty hammock sets designed specifically for superior weight capacity can provide valuable peace of mind.

2. Understanding Key Material Properties for Hammock Stands

Before diving into specific material options, it’s important to understand the key properties that determine a hammock stand’s performance and durability:

Tensile Strength: This measures how much pulling force a material can withstand before breaking—critical since hammocks create significant pulling tension. Steel typically offers 3-4 times the tensile strength of pine wood, making it exceptionally resistant to the pulling forces a hammock creates.

Yield Strength: This property indicates how much force a material can handle before becoming permanently deformed (bent). High yield strength prevents your stand from gradually bending over time.

Compressive Strength: This measures resistance to being pushed together or crushed—particularly important for the legs and supports of hammock stands that bear downward force.

Fatigue Resistance: The ability to withstand repeated loading and unloading cycles without weakening—essential since you’ll be getting in and out of your hammock regularly.

Weather Resistance: For outdoor stands, this encompasses resistance to:

– UV degradation (sun exposure)

– Moisture damage (rain, humidity)

– Temperature fluctuations (expansion/contraction)

Understanding these properties helps explain why certain materials excel for hammock stands while others may fall short. These factors directly impact the real-world performance you’ll experience and should guide your selection process based on your specific usage needs.

For more detailed guidance on how these material properties connect to proper setup, review our comprehensive hammock installation requirements safety guide.

3. Steel Hammock Stands: Unmatched Strength and Durability

When maximum strength is the priority, steel hammock stands reign supreme. These robust structures offer the highest weight capacity and overall durability of any material option on the market.

Carbon Steel vs. Stainless Steel

Carbon Steel (Powder-Coated)

– Superior absolute strength

– Typically supports 450-600 pounds

– More affordable than stainless steel

– Requires protective coating to prevent rust

– Heavier than other material options

Stainless Steel

– Excellent corrosion resistance without additional coating

– Slightly lower weight capacity (typically 400-550 pounds)

– Premium appearance with silver finish

– Higher price point

– Lower maintenance requirements

The thickness or gauge of steel dramatically impacts overall strength. Premium hammock stands typically use 12-14 gauge steel (lower numbers indicate thicker material), while budget options might use 16 gauge or higher, reducing weight capacity and longevity.

Weatherproofing is essential for steel stands, with powder coating offering the most durable protection. This process electrostatically applies dry paint powder, creating a hard finish that’s tougher than conventional paint. Quality powder coating can withstand years of outdoor exposure when properly maintained.

To preserve strength long-term, regular inspection of connection points and occasional touch-ups of protective coatings are recommended. Understanding the differences between various stand materials can help with decision-making, as explored in our detailed steel vs wood hammock stands comparison.

For those who need maximum strength but also value mobility, specialized portable hammock stands made from steel offer a balance of durability and convenience through clever folding designs.

4. Aluminum Hammock Stands: The Strength-to-Weight Champion

Aluminum stands offer an impressive balance of strength and portability, making them ideal for users who value mobility without compromising significantly on durability. The exceptional strength-to-weight ratio of aluminum allows for sturdy stands that are remarkably lightweight.

Aerospace-grade aluminum alloys, particularly series 6061 and 7075, deliver remarkable strength while keeping the overall weight manageable. A typical aluminum hammock stand weighs just 15-20 pounds compared to 25-35 pounds for steel alternatives of similar size. Despite their lighter weight, quality aluminum stands can reliably support between 300-450 pounds depending on the specific design and alloy used.

One of aluminum’s standout advantages is its natural corrosion resistance. Unlike steel, aluminum develops a thin oxide layer when exposed to air, protecting it from rust and deterioration—making it exceptionally well-suited for outdoor environments.

To maximize aluminum’s strength potential, manufacturers employ several key design strategies:

– Reinforced joints and connection points

– Strategic thickness allocation at high-stress areas

– Tubular designs that maximize strength while minimizing weight

While aluminum offers impressive performance, it’s important to note that it does have slightly lower absolute strength compared to steel and typically comes at a higher price point for equivalent strength. However, for many users, the significant weight savings and natural weather resistance more than justify the trade-off.

For those prioritizing portability alongside strength, our selection of lightweight hammock sets features aluminum stands designed to deliver impressive performance while remaining easy to transport.

5. Hardwood Hammock Stands: Natural Strength with Premium Aesthetics

Hardwood hammock stands offer a perfect marriage of impressive strength and unmatched natural beauty. These premium options bring warmth and character that metal stands simply cannot match, while still providing substantial weight support when properly constructed.

The strength profile of hardwood stands varies significantly based on the specific wood species used:

Teak: Renowned for exceptional strength and natural weather resistance due to high oil content. Supports weights up to 450-500 pounds while resisting rot and insect damage. Requires minimal maintenance but commands a premium price.

Cypress: Features natural chemicals that resist decay and insects. Offers excellent strength (typically supporting 400-450 pounds) with distinctive grain patterns and a moderate price point compared to teak.

Oak: Provides tremendous density and hardness, supporting weights up to 450 pounds. Features attractive grain but requires more diligent weather protection than teak or cypress.

Shorea/Balau: Similar to teak in strength and weather resistance but at a lower price point. Can reliably support 400-450 pounds with proper maintenance.

The inherent strength of hardwood stands depends heavily on wood density, grain structure, and moisture content. Quality hardwood stands typically feature thick supports and joints engineered to distribute weight efficiently. With proper care—including appropriate sealants and periodic maintenance—premium hardwood stands can last 10-20+ years, even in outdoor settings.

For outdoor use, weatherproofing treatments are essential to maintain strength integrity. Regular application of suitable wood sealants or oils prevents moisture absorption that could compromise structural integrity over time.

Discover our premium selection of wooden hammock stands that showcase the perfect combination of natural beauty and reliable strength. For those considering outdoor placement, our guide on whether it’s okay to leave your hammock outside provides valuable insights on maintaining wood stands in outdoor environments.

6. Engineered Wood Options: Strength Through Advanced Manufacturing

Engineered wood offers an innovative alternative to solid hardwood, often delivering superior strength through advanced manufacturing techniques. These materials are created by bonding wood layers or fibers with adhesives under heat and pressure, resulting in products with enhanced strength, consistency, and versatility.

Laminated Veneer Lumber (LVL) stands out as an excellent hammock stand material due to its remarkable load-bearing capacity. Created by bonding multiple thin wood veneers with their grains aligned, LVL can support weights of 450-550 pounds while offering greater dimensional stability than solid wood. This manufacturing process effectively eliminates weak points found in natural wood, such as knots or irregular grain patterns.

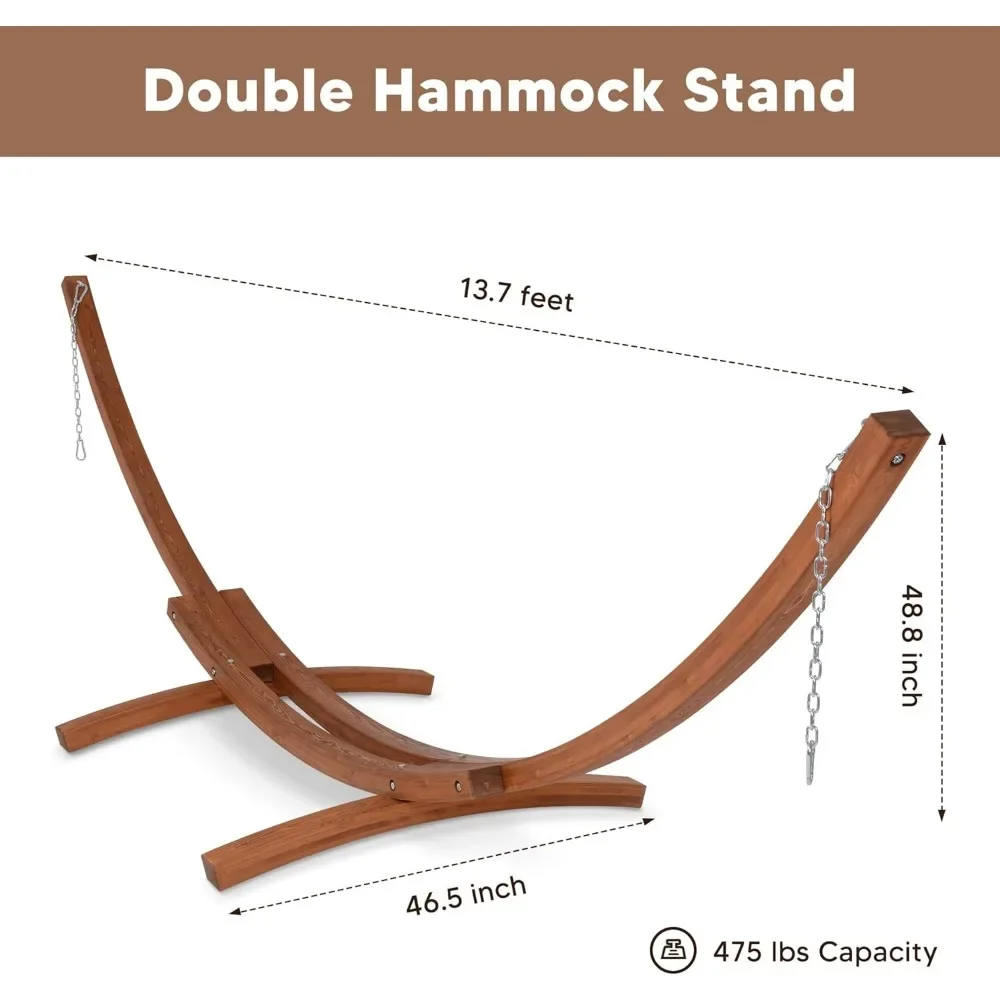

Glued Laminated Timber (Glulam) provides another strong option, particularly for curved hammock stand designs. By bonding smaller wood pieces together, manufacturers can create gracefully curved forms that maintain impressive strength. This technique allows for the beautiful arc shapes commonly seen in high-end hammock stands while supporting weights similar to solid hardwood options.

The strength advantages of engineered wood include:

- Greater consistency across the entire structure

- Enhanced resistance to warping and splitting

- Ability to create curved forms without compromising strength

- Superior dimensional stability with seasonal changes

For outdoor use, engineered wood requires proper sealing and weatherproofing, as the adhesives used in manufacturing can be vulnerable to moisture damage without adequate protection. However, with proper treatment, these materials offer excellent long-term durability.

Our collection of wooden arc stand hammock sets showcases how engineered wood can be shaped into stunning curved designs while maintaining exceptional strength characteristics.

7. Emerging Materials: Innovative Options for Hammock Stand Strength

The hammock stand market continues to evolve with innovative materials that offer unique combinations of strength, durability, and sustainability. These newer options provide alternatives to traditional materials while addressing specific performance needs.

Recycled Plastic Lumber

– Made from recycled plastic waste

– Exceptional weather resistance without maintenance

– Supports 300-400 pounds depending on design

– Completely resistant to rot, insects, and moisture

– Available in various colors and wood-like textures

– Heavier than wood but lighter than steel

Wood-Plastic Composites (WPC)

– Blend of wood fibers and thermoplastics

– Combines natural appearance with enhanced durability

– Typical weight capacity of 350-450 pounds

– Minimal maintenance requirements

– Resistant to splitting, cracking, and warping

– More environmentally sustainable than pure plastic options

Bamboo

– Technically a grass, not wood, with remarkable tensile strength

– Pound-for-pound tensile strength comparable to steel

– Supports 300-400 pounds when properly engineered

– Naturally resistant to warping

– Sustainable and rapidly renewable resource

– Requires proper treatment for outdoor durability

Hybrid Materials

– Innovative combinations of materials (metal frames with composite joints)

– Engineered to maximize the strengths of different materials

– Weight capacities typically 350-450 pounds

– Often designed for specific environments or use cases

– Can offer unique aesthetic and functional benefits

These emerging options often provide excellent weather resistance with minimal maintenance requirements, making them particularly attractive for outdoor settings. For those interested in highly durable options for outdoor use, our guide to weather-resistant materials for heavy-duty stands provides in-depth information about material performance in challenging environments.

Dark Wood Hammock Sets, Porch Swing Chair Sets

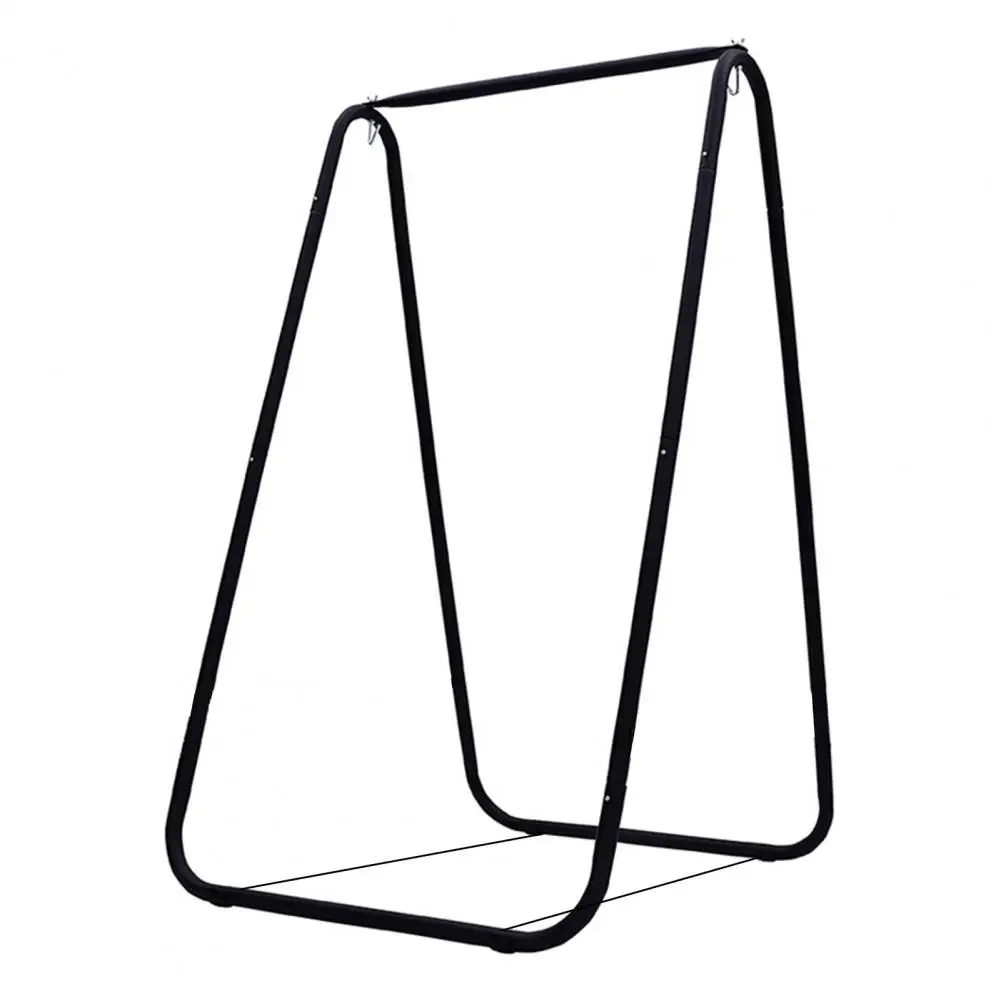

$653.82 Select options This product has multiple variants. The options may be chosen on the product pageA-Frame Stand Hammock Sets, Swinging Hammock Chair Sets

$154.62 Select options This product has multiple variants. The options may be chosen on the product pageLight Wood Hammock Sets, Swinging Hammock Chair Sets

$1,359.35 Select options This product has multiple variants. The options may be chosen on the product pageClassic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

$286.31 Select options This product has multiple variants. The options may be chosen on the product page

8. Comparative Strength Analysis: Finding Your Ideal Hammock Stand Material

When selecting the ideal hammock stand material, understanding how different options compare across key metrics helps make an informed decision based on your specific needs:

| Material | Weight Capacity | Weather Resistance | Portability | Maintenance | Relative Cost |

|---|---|---|---|---|---|

| Heavy-gauge Steel | 450-600+ lbs | Good (with coating) | Poor | Moderate | Moderate |

| Stainless Steel | 400-550 lbs | Excellent | Poor | Low | High |

| Aluminum | 275-450 lbs | Very Good | Excellent | Low | Moderate-High |

| Premium Hardwoods | 350-500 lbs | Good (with treatment) | Poor | High | High |

| Engineered Woods | 400-550 lbs | Good (with treatment) | Moderate | Moderate | Moderate-High |

| Composites/Recycled Plastic | 300-450 lbs | Excellent | Moderate | Very Low | Moderate |

Best For Maximum Absolute Strength:

Heavy-gauge steel (12-14 gauge) with quality powder coating offers unmatched weight capacity and durability. The solid construction handles even the most demanding uses, though the significant weight makes these stands less portable.

Best For Portable Strength:

Aircraft-grade aluminum (especially 7075 series) provides the optimal balance of strength and mobility. While supporting less weight than steel, quality aluminum stands offer impressive capacity while remaining light enough to transport easily.

Best For Weather-Resistant Strength:

Stainless steel and quality composites excel in challenging outdoor environments. Stainless steel offers superior strength with natural corrosion resistance, while composites provide excellent weather resistance with moderate strength and minimal maintenance.

Best For Aesthetic Strength:

Premium hardwoods like teak and cypress combine impressive weight support with unmatched visual appeal. These natural options bring warmth and character to any space while providing reliable strength when properly maintained.

Best Budget Strength:

Powder-coated steel delivers excellent strength-per-dollar value, making it the most economical option without significantly compromising on weight capacity. For wood lovers on a budget, pressure-treated pine offers reasonable strength at a lower price point than hardwoods.

For comprehensive information about safety considerations related to stand materials and construction, our indoor and outdoor hammock safety guide provides essential guidance.

9. Beyond Materials: Construction Factors That Impact Stand Strength

While material selection is crucial, even the strongest materials can fail if design and construction quality are subpar. Several key construction factors work together with material properties to determine the true strength of a hammock stand:

Joint Quality and Design: The connections between components are typically where failures occur—not in the materials themselves. Welded joints in metal stands are generally stronger than bolted connections but require quality craftsmanship. For wooden stands, mortise and tenon joints typically offer superior strength compared to simple screwed connections.

Base Width and Geometry: Wider bases provide greater stability regardless of material. The overall geometry of the stand—particularly the distribution of forces through triangulation and support positioning—dramatically impacts effective strength. A well-designed aluminum stand can sometimes outperform a poorly designed steel one despite the material difference.

Weight Distribution Engineering: How effectively a stand distributes the user’s weight across its structure significantly impacts its functional strength. Quality stands incorporate strategic reinforcement at high-stress points and tension-balancing features that maximize the material’s strength potential.

Assembly Precision: Even the strongest materials can fail if improperly assembled. Following manufacturer guidelines precisely ensures that the theoretical strength of the materials translates to real-world performance. This includes using all specified hardware and tightening connections to recommended specifications.

Quality Control Standards: Reputable manufacturers implement rigorous testing protocols that ensure consistent strength across their products. This includes load testing, material verification, and dimensional accuracy checks that prevent weak points from reaching consumers.

Our collection of A-frame stand hammock sets showcases designs that optimize structural strength through thoughtful engineering that complements quality materials.

10. Maintaining Material Strength: Care Tips for Long-Term Durability

Proper maintenance is essential for preserving the strength and extending the lifespan of your hammock stand, regardless of material. Following these material-specific care guidelines will help ensure your stand remains strong and reliable for years to come:

Steel Stand Maintenance:

– Inspect regularly for rust spots, especially at joints and connection points

– Touch up any scratches in powder coating promptly to prevent corrosion

– Tighten all bolts and connections seasonally

– Apply rust inhibitor to exposed metal surfaces annually

– Store in a dry location during extended periods of non-use

Aluminum Stand Maintenance:

– Clean with mild soap and water to remove dirt and debris

– Check for small cracks that might develop at stress points

– Protect from impacts that could dent or deform the metal

– Keep moving parts lubricated if your stand has folding mechanisms

– No need for rust protection, but avoid prolonged exposure to salt water

Hardwood Stand Maintenance:

– Apply quality wood sealant or oil annually (twice yearly for high-exposure areas)

– Clean with gentle wood cleaner to remove dirt and prevent mold

– Check for splinters or cracks and sand smooth as needed

– Store indoors or under cover during severe weather conditions

– Keep wood elevated from ground contact to prevent moisture absorption

Engineered Wood Maintenance:

– Seal all surfaces thoroughly, especially end grains and connection points

– Inspect for delamination (layer separation) regularly

– Keep protected from standing water

– Re-seal annually or when water stops beading on the surface

– Store with proper support to prevent warping

Composite Material Maintenance:

– Clean occasionally with soap and water

– Inspect for UV degradation (color fading, surface roughening)

– No sealing required, but protective covers extend aesthetic lifespan

– Keep free of organic debris that could cause staining

For more detailed information about material durability in various weather conditions, our guide on best materials for outdoor hammocks provides valuable insights for maintaining your hammock system.

11. Expert Recommendations for Ultimate Hammock Stand Strength

Based on extensive testing and real-world performance evaluation, these definitive recommendations will help you select the optimal material for your specific hammock stand needs:

For Maximum Absolute Strength: Heavy-gauge steel (12-14 gauge) with quality powder coating offers unmatched durability and weight support. Look for fully welded (not just bolted) construction and a minimum 500-pound weight capacity for superior performance. This option is ideal when strength is the absolute priority and portability is less important.

For Balanced Strength and Portability: Aircraft-grade aluminum (particularly 7075-T6 alloy) with reinforced joints provides the best strength-to-weight ratio. These stands typically weigh 40-60% less than comparable steel options while still supporting 300-400 pounds, making them ideal for those who value mobility without significantly compromising strength.

For Long-Term Outdoor Strength: Stainless steel or premium teak/shorea wood with proper maintenance delivers exceptional outdoor durability. Stainless steel requires minimal care while resisting corrosion indefinitely. Premium hardwoods offer excellent strength while aging beautifully when properly maintained with appropriate sealants.

For Aesthetic Strength in Permanent Installations: Quality hardwoods like cypress or oak combine impressive strength with superior visual appeal. These materials support 350-500 pounds while providing a warmth and character that metal options cannot match, making them perfect for permanent indoor or covered outdoor settings.

Remember that regardless of material, always respect manufacturer weight ratings and regularly inspect your stand for signs of wear or damage. Never exceed recommended weight capacities, even with the strongest materials, as dynamic forces during use can temporarily exceed static load ratings.

Browse our collection of heavy-duty hammock sets featuring stands designed specifically for maximum strength and performance in demanding conditions.

12. Is Your Current Hammock Stand Strong Enough? Safety Assessment Guide

If you already own a hammock stand, this practical checklist will help you evaluate its current condition and determine if it’s still providing adequate strength and safety:

Material Identification and Condition Assessment:

– Identify your stand’s primary material (steel, aluminum, wood, etc.)

– Check for visible damage: rust, cracks, splinters, deformation

– Evaluate protective coatings: Is paint/powder coating intact? Is wood sealant still effective?

– Look for stress indicators: metal fatigue, wood splitting, or delamination

Weight Capacity Verification:

– Locate manufacturer weight rating (typically on packaging or instructions)

– Compare to your current usage needs (combined weight of users plus hammock)

– Consider adding a 20% safety margin to account for dynamic forces

Joint and Connection Inspection:

– Examine all connection points for looseness or damage

– Tighten any loose bolts or screws to manufacturer specifications

– Check welds for cracks or separation

– Verify wooden joints remain snug and aligned

Simple Strength Tests:

– Gently bounce test (without a person in the hammock)

– Check for excessive flexing or creaking under normal load

– Verify the stand remains stable and level on your surface

– Confirm base legs remain firmly planted during entry and exit

If you notice significant material deterioration, unstable connections, or concerning movement during use, it may be time to reinforce or replace your stand. Safety should always take priority over extending the life of a compromised stand.

For information about optimal stand placement to maximize stability and safety, our guide on perfect hammock placement for home and garden provides valuable insights.

13. Are Wooden Hammock Stands as Strong as Metal? The Truth About Natural Materials

This common question deserves a nuanced answer, as properly selected and constructed wooden stands can indeed rival metal in practical strength for most users.

While steel offers superior tensile strength on a pound-for-pound basis, premium hardwoods like teak, ipe, or white oak provide excellent compressive strength—often exceeding that of aluminum and approaching steel. This allows quality wooden stands to support impressive weight capacities of 350-500 pounds when properly designed.

The key factors that influence wooden stand strength include:

Wood Species Selection: Dense hardwoods provide dramatically better strength than softwoods. The difference between pine and oak, for example, can mean a 30-50% difference in weight capacity.

Grain Orientation: Wood is significantly stronger when force is applied parallel to the grain rather than perpendicular. Quality wooden stands are engineered with grain direction optimized for maximum strength.

Moisture Content: Properly dried wood (8-12% moisture content) offers substantially better strength than green wood or wood that has absorbed excessive moisture over time.

Joint Design: Wooden stands with traditional joinery techniques like mortise and tenon connections often outperform those assembled with simple screws or bolts.

For practical everyday use, premium wooden stands provide more than sufficient strength for most users, while offering aesthetic benefits that metal cannot match. The choice ultimately depends on your specific priorities—maximum absolute strength (metal) versus strength with superior aesthetics (wood).

Explore our collection of classic wooden stand hammock sets to experience the perfect combination of natural beauty and reliable strength.

14. How Much Weight Can Different Hammock Stand Materials Really Hold?

Understanding the realistic weight capacities of different hammock stand materials helps ensure you select an option that meets your specific needs safely:

Heavy-Duty Steel: The strongest option available, quality heavy-gauge steel stands typically support 450-600+ pounds. These stands use thick metal (often 12-14 gauge) with reinforced connection points and wide bases to maximize stability under load.

Standard Steel: More common in mid-range products, standard steel stands generally support 300-450 pounds. The thickness of the steel and quality of welds significantly impact where in this range a particular stand will fall.

Aluminum: Despite being lighter, quality aluminum stands can support 275-450 pounds depending on the specific alloy and design. Aircraft-grade aluminum (7075-T6) offers the highest capacity, while more common 6061 alloy provides moderate strength at a lower price point.

Premium Hardwoods: Quality hardwood stands typically support 350-500 pounds, with exact capacity depending on wood species, design, and construction quality. Denser woods like teak and ipe offer higher capacities than lighter hardwoods.

Engineered Woods: Well-designed engineered wood stands support 400-550 pounds, sometimes exceeding natural wood due to their consistent strength properties and strategic reinforcement.

Composites/Alternatives: Modern composite materials generally support 300-450 pounds, balancing moderate strength with excellent weather resistance and minimal maintenance.

It’s important to note that manufacturers typically build in safety factors of 1.5-2x when rating weight capacities, meaning a stand rated for 400 pounds has likely been tested to at least 600 pounds in static load conditions. However, dynamic forces during use (swinging, bouncing) can temporarily create loads exceeding static weight, which is why staying within rated capacities is essential.

For those needing stands designed specifically for higher weight capacity, our double two-person hammock sets feature reinforced stands built to accommodate multiple users safely.

15. Weather Resistance: Which Hammock Stand Materials Last Longest Outdoors?

For outdoor hammock enthusiasts, weather resistance is nearly as important as strength in determining long-term durability. Here’s how common stand materials rank in their ability to withstand the elements:

1. Stainless Steel and Aluminum offer superior natural weather resistance. The chromium in stainless steel forms a protective oxide layer that prevents corrosion, while aluminum naturally develops a protective aluminum oxide coating. Both can remain outdoors for years with minimal maintenance.

2. Quality Composites like recycled plastic lumber and wood-plastic composites are engineered specifically for outdoor exposure. These materials resist UV damage, don’t absorb moisture, and maintain strength through temperature extremes. They won’t rot, splinter, or rust regardless of conditions.

3. Treated Hardwoods like teak and cypress contain natural oils and chemicals that resist decay. Teak’s high oil content makes it naturally water-resistant, while cypress contains cypressene, a natural preservative. With occasional maintenance, these woods can last 15-20+ years outdoors.

4. Powder-Coated Steel offers excellent weather resistance as long as the coating remains intact. Quality powder coating can protect steel for 5-10+ years, but any chips or scratches create vulnerability to rust if not promptly addressed.

5. Untreated or Minimally Treated Woods require the most maintenance and have the shortest outdoor lifespan. Regular sealing (every 6-12 months) is essential to prevent moisture absorption that leads to rot, warping, and strength degradation.

Regional climate significantly impacts material selection. In coastal areas with salt spray, stainless steel and composites offer significant advantages. In hot, sunny regions, UV-resistant materials like composites or aluminum prevent degradation from intense sun exposure. In humid environments, naturally rot-resistant woods or metals prevent moisture damage.

For comprehensive information about protecting different stand materials from weather damage, our guide on waterproof materials for hammock protection provides valuable weatherproofing strategies.

16. Final Verdict: Choosing the Right Material for Your Hammock Stand

After examining the strength properties of various hammock stand materials, several clear recommendations emerge based on specific priorities:

For maximum absolute strength regardless of other factors, heavy-gauge steel stands with quality powder coating deliver unmatched performance. These stands offer the highest weight capacities (450-600+ pounds) and exceptional durability, making them ideal when strength is the primary consideration.

For those balancing strength with portability, aircraft-grade aluminum provides the best combination of weight support and mobility. While slightly less strong than steel, quality aluminum stands support 275-450 pounds while remaining light enough for one person to move easily—perfect for those who reposition their hammock frequently.

For permanent outdoor installations, stainless steel or premium weather-resistant hardwoods like teak offer the ideal combination of strength and environmental durability. These materials maintain their structural integrity through years of exposure to the elements with minimal maintenance requirements.

For those valuing aesthetics alongside strength, quality hardwood stands in cypress, oak, or similar species provide visual warmth that complements natural settings while still offering impressive weight support of 350-500 pounds when properly constructed.

Regardless of material choice, remember that construction quality ultimately determines real-world performance. Even the strongest materials can fail if poorly designed or assembled. Always follow manufacturer guidelines for assembly and weight limits, and perform regular maintenance appropriate to your chosen material.

With proper selection and care, your hammock stand will provide years of safe, reliable performance—creating the perfect foundation for countless hours of relaxation and enjoyment.

Explore our complete collection of hammock stands in various materials to find the perfect option for your specific needs and preferences.