1. Introduction to Hammock Waterproofing

Picture this: you’re peacefully swaying in your hammock when dark clouds suddenly gather overhead. Minutes later, you’re scrambling to pack up as rain pours down, soaking both you and your gear. This all-too-common scenario highlights why proper waterproofing is crucial for hammock campers.

Waterproofing your hammock setup isn’t just about staying dry—it’s about ensuring comfort, safety, and extending the lifespan of your outdoor gear. Without adequate protection, even premium hammocks can become unusable during wet conditions, potentially ruining your outdoor experience.

There are two fundamental approaches to keeping your hammock dry:

– Rain protection systems (tarps and rainflies) that create a waterproof barrier above your hammock

– Water-resistant hammock materials that help repel moisture and dry quickly

Proper indoor and outdoor hammock placement works hand-in-hand with your waterproofing strategy, as even the best materials need to be properly positioned to effectively resist water.

In this comprehensive guide, we’ll explore:

– Essential waterproofing terminology and ratings

– Premium and standard materials for hammock tarps

– Water-resistant options for hammock bodies

– How to select the right waterproof materials for your needs

– Maintenance techniques to ensure lasting protection

With industry studies showing that proper waterproofing can extend gear lifespan by up to 60%, understanding these materials isn’t just convenient—it’s an investment in your outdoor enjoyment.

2. Understanding Hammock Waterproofing Fundamentals

Before diving into specific materials, it’s important to understand the basic principles of hammock waterproofing. Most effective hammock systems use a two-component approach to water protection:

Hammock Bodies vs. Rainflies

Hammock bodies are typically designed to be water-resistant rather than fully waterproof. This design choice prioritizes comfort, breathability, and quick-drying properties. They can handle light moisture and humidity but aren’t meant to withstand direct rainfall.

Rainflies/tarps serve as your primary waterproof barrier. Positioned above your hammock, these specially designed covers intercept rain before it reaches you or your hammock. A properly sized rainfly with adequate coverage is essential for true waterproof protection.

Key Waterproofing Terminology

Hydrostatic Head (HH) Rating: This measurement indicates how waterproof a fabric is by measuring how much water pressure it can withstand before leaking. Expressed in millimeters, it represents the height of a water column the fabric can support:

– 1,000mm: Resistant to light rain

– 2,000-3,000mm: Handles moderate rainfall

– 5,000mm+: Withstands heavy, driving rain

Denier (D): This unit measures the thickness and weight of individual threads in a fabric. Higher denier means thicker, more durable, but heavier material:

– 15-30D: Ultralight but less durable

– 40-70D: Balanced weight/durability

– 70D+: Heavy-duty and very durable

Waterproofing Technologies:

– PU (Polyurethane) Coating: A synthetic layer applied to fabrics that creates a waterproof barrier

– Silicone Impregnation: Silicone is infused into the fabric for superior water repellency

– DWR (Durable Water Repellent) Finish: A treatment that causes water to bead and roll off rather than soak in

Seam Sealing: Even with waterproof materials, water can penetrate through needle holes at the seams. Seam sealing uses tape or liquid sealant to cover these vulnerable points.

Understanding these fundamentals helps you evaluate various outdoor hammock materials and make informed choices about which waterproofing solution best suits your needs.

3. Premium Waterproof Fabrics for Hammock Tarps

When it comes to superior rain protection for your hammock, two premium materials stand above the rest, each offering exceptional waterproofing with different characteristics and price points.

Dyneema Composite Fabric (DCF)/Cuben Fiber

DCF represents the pinnacle of ultralight waterproof technology. This non-woven composite material consists of Dyneema fibers sandwiched between polyester films, creating an incredibly strong yet lightweight fabric.

Composition and Manufacturing:

Unlike woven fabrics, DCF is created by laying Dyneema fiber grids between polyester films and bonding them under heat and pressure. This unique construction eliminates the need for additional waterproof coatings.

Key Properties:

– Inherently Waterproof: Water resistance is built into the material itself, not reliant on coatings that can wear off

– Ultralight: Often 30-50% lighter than comparable silnylon options

– Zero Stretch: Maintains tension when wet, unlike nylon options that sag

– Exceptional Strength-to-Weight: Pound for pound, stronger than steel

Limitations:

– Extremely expensive (often 3-5x the cost of other premium materials)

– Creates notable noise during rain or wind

– Difficult to repair in the field

– Doesn’t pack down as small as woven fabrics

– Less abrasion resistant than woven fabrics

Best For: Ultralight backpackers where every ounce matters and budget is less of a concern. A 10’×10’ DCF tarp typically weighs around 7 ounces (198g), compared to 16 ounces (453g) for comparable silnylon.

Silnylon

Silnylon (silicone-impregnated nylon) represents an excellent balance of performance and cost for premium hammock rainflies.

Composition and Manufacturing:

This material is created by impregnating nylon ripstop fabric with silicone on both sides. The silicone thoroughly permeates the fabric rather than just coating the surface.

Key Properties:

– Superior Water Repellency: Creates excellent beading effect where water rolls off

– Good Strength: Offers strong tear resistance and puncture protection

– Lightweight: Significantly lighter than PU-coated options

– Reasonable Cost: Premium performance at moderate price point

Limitations:

– Stretches when wet, requiring readjustment during rainfall

– Requires more careful seam sealing than some alternatives

– Less UV resistant than polyester-based options

– Requires careful storage to maintain properties

Best For: General backpackers and hammock campers seeking an excellent balance of weight, performance, and cost. Price ranges typically fall between $80-150 for a quality hammock tarp, depending on size and design.

The camping hammocks and stands available today often feature these premium materials for their rain protection components, with premium tarps using these fabrics to create comprehensive weather protection systems.

4. Standard Waterproof Materials for Hammock Tarps

While premium options offer exceptional performance, standard waterproof materials provide reliable protection at more accessible price points. These materials represent the backbone of most commercial hammock rain protection systems.

Silpoly

Silicone-impregnated polyester (silpoly) has become increasingly popular as an alternative to silnylon, offering some distinct advantages.

Composition and Manufacturing:

Similar to silnylon, this material features polyester fabric impregnated with silicone. The key difference lies in using polyester rather than nylon as the base fabric.

Key Properties:

– Minimal Stretch When Wet: Unlike silnylon, silpoly maintains its tension in rainy conditions

– Superior UV Resistance: Polyester naturally resists UV degradation better than nylon

– Dimensionally Stable: Maintains shape and tension in changing conditions

– Competitive Weight: Often comparable to silnylon in overall weight

Limitations:

– Slightly less tear strength than equivalent denier silnylon

– Less “natural” drape than silnylon

– May feel stiffer to handle

– Often requires more careful staking due to less stretch

Best For: Hammock campers who prioritize simplicity of setup and maintenance, especially those camping in areas with unpredictable weather changes. The minimal stretch means less readjustment during rainstorms.

PU-Coated Nylon or Polyester

Polyurethane-coated fabrics represent the most common and economical waterproofing approach in the outdoor industry.

Composition and Manufacturing:

These materials feature a layer of polyurethane applied to one or both sides of nylon or polyester fabric. The coating creates a solid waterproof barrier.

Key Properties:

– Affordable: Significantly less expensive than silicone-treated fabrics

– Widely Available: Used in many entry and mid-level products

– Good Initial Waterproofing: Provides reliable protection when new

– Various Thickness Options: Available in many denier ratings

Limitations:

– Heavier than silicone-treated equivalents

– Coating degrades over time, particularly with UV exposure

– Less breathable, leading to increased condensation

– Requires more careful storage to prevent coating degradation

– Less packable due to coating stiffness

Best For: Occasional hammock campers, those on tighter budgets, or campers who primarily experience mild weather conditions. PU-coated tarps often cost 30-50% less than their silicone-impregnated counterparts.

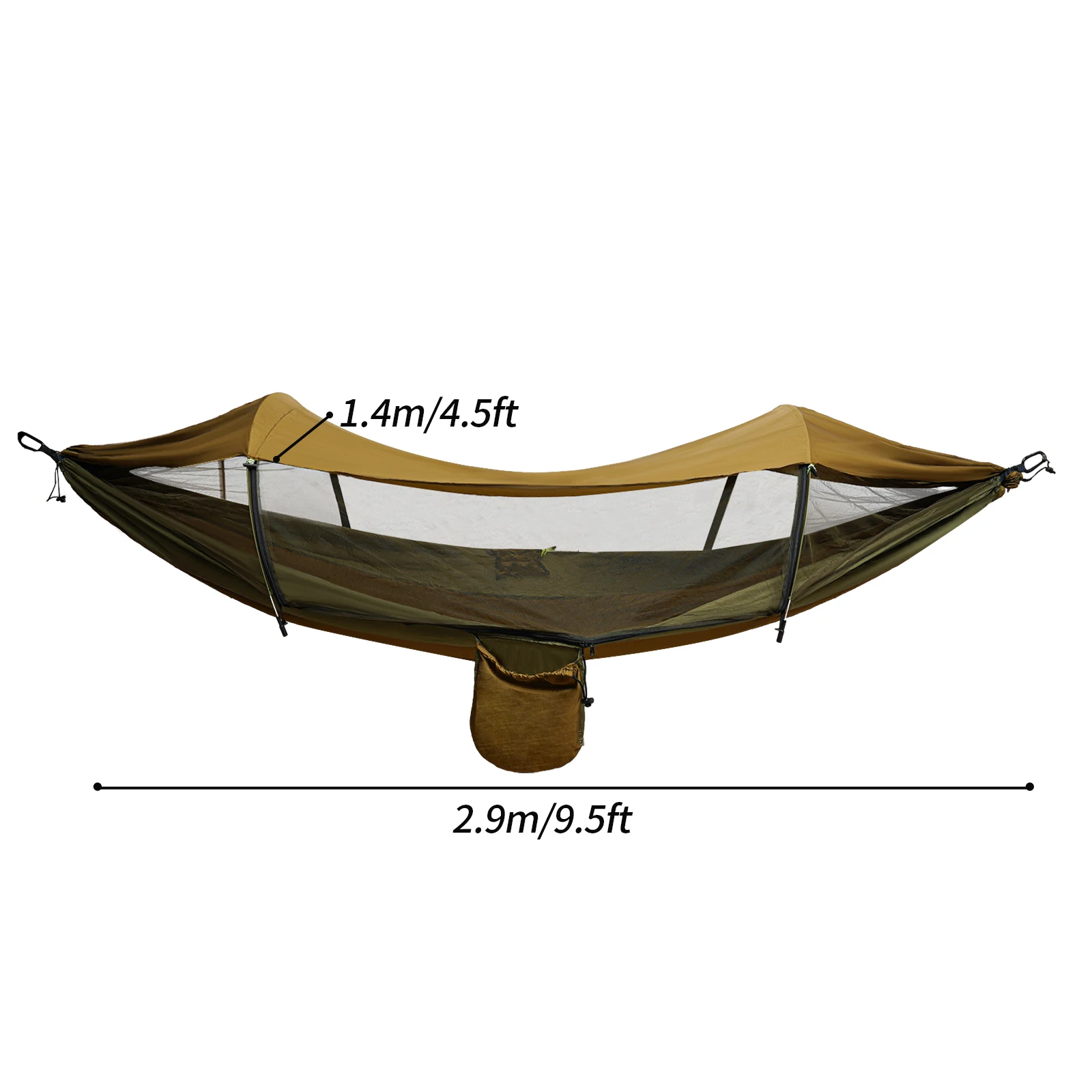

Many camping hammock sets with bug nets pair these standard waterproof materials with integrated insect protection, creating versatile systems for multiple conditions without breaking the bank.

When examining PU-coated materials, look for signs of coating degradation such as flaking, stickiness, or a powdery residue—these indicate it’s time for replacement, as water protection has likely been compromised.

5. Water-Resistant Materials for Hammock Bodies

While tarps handle the primary rain protection, the hammock body itself also plays an important role in your comfort during wet conditions. Rather than being fully waterproof (which would create condensation issues), hammock bodies are typically designed to be water-resistant and quick-drying.

Ripstop Nylon with DWR Finish

Ripstop nylon forms the foundation of most quality hammock bodies on the market today, often enhanced with a Durable Water Repellent (DWR) finish.

Properties That Make It Suitable:

– Breathability: Allows air circulation to prevent the clammy feeling of fully waterproof materials

– Comfort Against Skin: Soft texture remains comfortable even in humid conditions

– Fast-Drying: Sheds moisture quickly when exposure occurs

– Lightweight: Minimizes pack weight while maintaining durability

– Water Resistance: DWR treatment causes light moisture to bead up rather than soak through

The DWR finish doesn’t make the hammock waterproof but provides enough resistance to keep you dry from light mist or morning dew. It also prevents the hammock from absorbing excessive moisture from the environment, which keeps it feeling dry to the touch.

Polypropylene for Hammock Bodies

Some manufacturers utilize polypropylene for hammock bodies, particularly for more budget-friendly options.

Inherent Hydrophobic Properties:

Polypropylene naturally repels water without requiring additional treatments. This inherent hydrophobia makes it particularly suitable for humid environments where materials like cotton would become heavy with moisture.

Advantages:

– Naturally Water-Resistant: Repels water molecules at a material level

– Mildew Resistant: Highly resistant to mold and mildew growth

– Quick-Drying: Dries significantly faster than natural fibers

– Affordable: Often less expensive than treated nylon options

– UV Stabilized: Better versions include UV stabilizers to prevent degradation

However, polypropylene typically feels less premium against the skin compared to quality nylon and may not provide the same durability in high-stress applications.

Why Truly Waterproof Hammock Bodies Are Rare

Fully waterproof hammock bodies create more problems than they solve. When a material blocks water in both directions, it also prevents sweat and body moisture from escaping, leading to uncomfortable condensation inside the hammock. This moisture can make you feel colder than if the material were simply water-resistant and breathable.

For complete protection, complete camping hammock systems combine water-resistant hammock bodies with properly sized waterproof tarps, creating the ideal balance of protection and comfort.

6. Comprehensive Material Comparison Chart

When selecting waterproof materials for your hammock system, weighing the various properties against your specific needs helps make the optimal choice. This comparison chart breaks down the key differences between the major tarp materials discussed:

| Material | Waterproofness | Weight | Durability | Wet Stretch | Packability | Relative Cost | Key Advantages | Primary Disadvantages |

|---|---|---|---|---|---|---|---|---|

| Silnylon | Excellent (3000-4000mm HH) | Light (1.3-1.5oz/yd²) | Good | High stretch (10-15%) | Very Good | Moderate | Best strength-to-weight ratio | Requires readjustment when wet |

| Silpoly | Excellent (2500-3500mm HH) | Light (1.2-1.5oz/yd²) | Good | Minimal stretch (1-3%) | Good | Moderate | Dimensional stability when wet | Slightly lower tear strength than silnylon |

| Dyneema (DCF) | Outstanding (8000+mm HH) | Ultralight (0.5-0.8oz/yd²) | Fair to Good | No stretch (0%) | Fair | Very High | Lightest waterproof option | Expensive, noisy, difficult to repair |

| PU-Coated Nylon | Good (1500-3000mm HH) | Moderate (2.0-2.5oz/yd²) | Fair | Moderate stretch (5-10%) | Fair | Low | Most affordable | Coating degrades over time |

| PU-Coated Polyester | Good (1500-3000mm HH) | Moderate (2.0-2.5oz/yd²) | Fair | Low stretch (2-4%) | Fair | Low | Better UV resistance than nylon | Heavier, less packable |

This comparison highlights why there’s no single “best” material—each offers a different balance of properties that may be ideal depending on your priorities. For example, while DCF offers the lightest weight, its cost may be prohibitive for many users, making silnylon or silpoly more practical choices.

Understanding hammock installation requirements and safety also influences material selection, as different setups may place varying demands on your waterproofing system.

7. Selecting the Right Waterproof Material for Your Setup

Choosing the optimal waterproof material depends on your specific usage scenarios, environmental conditions, and personal priorities. Here’s a decision framework to help guide your selection:

Based on Primary Use Case

For Ultralight Backpacking:

– Best Option: Dyneema Composite Fabric (DCF) for those with larger budgets

– Value Option: 15-20D Silpoly for the best balance of weight and cost

– Budget Option: 30D PU-coated polyester if weight is less critical

For General Backpacking/Camping:

– Best Option: 20-30D Silnylon for excellent all-around performance

– Value Option: 30D Silpoly for minimal adjustment during rain

– Budget Option: 40-70D PU-coated nylon for durability at lower cost

For Car Camping/Backyard Use:

– Best Option: 40-70D Silpoly for durability and low maintenance

– Value Option: Heavy-duty (70D+) PU-coated polyester for longevity

– Budget Option: Standard PU-coated nylon tarps for occasional use

Climate and Weather Considerations

Frequent Heavy Rain Regions:

Materials with higher hydrostatic head ratings (4000mm+) become more important. Silnylon offers excellent water repellency but requires adjustment during extended rain. Silpoly maintains tension better during prolonged downpours.

High Humidity Environments:

For hammock bodies, materials with intrinsic moisture resistance like polypropylene or treated ripstop nylon prevent that clammy feeling. For tarps, silicone-treated fabrics generally handle persistent humidity better than PU coatings, which can degrade faster in constantly moist conditions.

Critical Trade-offs to Consider

Weight vs. Durability:

Ultralight materials (under 1.0oz/yd²) sacrifice some durability. For rough conditions or extended trips, consider going up one weight class for longevity.

Cost vs. Longevity:

Premium materials like DCF and silicone-impregnated fabrics cost more initially but typically last longer than PU-coated options, especially with proper care.

Packability vs. Coverage:

Larger tarps provide better protection but add weight. Consider how materials pack down—DCF is light but bulky, while silnylon compresses exceptionally well.

Remember that tarp size and design (asymmetrical, diamond, hexagonal, etc.) significantly impact protection regardless of material choice. Even the best material won’t keep you dry if the tarp isn’t properly sized for your setup.

For lightweight adventures, ultralight camping hammock sets often feature optimized material selections that balance protection with minimal weight.

8. Maintenance of Waterproof Hammock Materials

Proper care significantly extends the life of your waterproof hammock materials. Following these maintenance guidelines will help preserve their water-resistant properties for years of reliable service.

Proper Cleaning Techniques

Different materials require specific cleaning approaches:

For Silicone-Treated Fabrics (Silnylon/Silpoly):

– Hand wash using cool water and mild, non-detergent soap

– Avoid machine washing which can damage silicone impregnation

– Never use bleach or fabric softeners

– Gently agitate by hand and rinse thoroughly

For Dyneema Composite Fabric (DCF):

– Wipe clean with a damp cloth and mild soap solution

– For stubborn dirt, use a soft brush with gentle pressure

– Avoid machine washing which can damage laminate layers

– Rinse with clean water to remove all soap residue

For PU-Coated Materials:

– Hand wash with lukewarm water (not hot) and mild soap

– Machine washing on gentle cycle is acceptable occasionally

– Use technical wash products designed for outdoor gear

– Avoid standard laundry detergents which leave residue

Drying Best Practices

Proper drying is crucial for maintaining waterproof properties:

- Air dry all waterproof materials hanging loosely

- Never use machine dryers, even on low heat settings

- Avoid direct sunlight for extended periods during drying

- Ensure complete drying before storage to prevent mildew

- Turn tarps inside out halfway through drying process

- Shake periodically during drying to prevent water pooling

Long-term Storage Guidelines

How you store your waterproof hammock materials significantly impacts their lifespan:

- Store loosely rolled rather than tightly compressed

- Keep in cool, dry location away from direct sunlight

- Avoid folding repeatedly along the same lines which weakens materials

- Use breathable storage bags rather than airtight containers

- Remove from stuff sacks for long-term storage

- Clean thoroughly before extended storage periods

Re-waterproofing Techniques

Even the best materials eventually need waterproofing refreshed:

For DWR-Treated Materials:

– Apply spray-on DWR refresher when water stops beading

– Heat treatment with hairdryer on low setting helps reactivate existing DWR

– Focus on high-wear areas that show diminished water resistance

For Seam Sealing:

– Check seams annually for deterioration

– Apply silicone-based seam sealer to silnylon/silpoly

– Use polyurethane-based sealer for PU-coated materials

– Clean and dry seams thoroughly before applying new sealant

With proper maintenance, quality waterproof materials can provide reliable protection for 5-10 years of regular use, making them a worthy investment for anyone serious about hammock camping.

The question of leaving hammocks outside is particularly relevant when considering waterproof materials, as even the best waterproofing will eventually degrade with constant exposure to the elements.

9. Advanced Waterproofing Techniques for Hammock Systems

Beyond material selection, several specialized techniques can enhance your hammock’s water protection system, addressing common weak points and problem areas.

Supplemental Waterproofing Approaches

Drip Lines:

These simple yet effective additions prevent water from tracking along your suspension system into your hammock. Attach small pieces of cordage at strategic points on your suspension, creating a path for water to drip to the ground instead of continuing to your hammock. Effective materials include:

– Twisted mason’s line

– Paracord segments

– Purpose-made silicone drip rings

Underquilt Protectors:

These lightweight waterproof layers shield your insulation from moisture coming from below. They create a barrier between your underquilt and environmental moisture without compromising breathability. Ideal materials include:

– Lightweight silpoly (0.9-1.2 oz/yd²)

– Breathable water-resistant fabrics

– DCF for ultralight applications

Double-Layer Protection:

For extreme conditions, consider a dual-barrier approach with:

– Primary overhead tarp for rain protection

– Secondary “doors” or end caps to block wind-driven rain

– Hammock sock systems that create a full microclimate

Specialized Solutions for Problem Areas

Ridge Line Water Channeling:

Water often pools along ridgelines or finds ways through attachment points. Solutions include:

– Silicone-treated continuous ridgelines that repel water

– Properly tensioned cat-cut tarps that direct water away from center

– Drip-prevention hardware at attachment points

Entry Point Protection:

The most vulnerable moment for water entry is during entry/exit. Address this with:

– Extended “beak” or porch features on tarps

– Proper tarp tensioning techniques

– Strategic positioning relative to wind direction

Tree Strap Water Diversion:

Tree straps can channel significant water toward your hammock. Prevent this by:

– Using water-resistant strap materials

– Installing strap covers or “rain bibs” above attachment points

– Positioning drip lines immediately below strap connections

Condensation Management

Condensation can make you just as wet as rain. Effective management techniques include:

- Maintaining adequate ventilation by proper tarp positioning

- Using appropriate tarp configurations for conditions (storm mode vs. fair weather setup)

- Selecting materials with appropriate breathability

- Creating proper distance between tarp and hammock

- Adjusting setup based on temperature and humidity forecasts

Heavy-duty hammock sets often incorporate these advanced waterproofing techniques into their design, creating systems that perform reliably even in challenging conditions.

Camping Hammock Sets with Bug Net, Ultralight Camping Hammock Sets

$139.72 Select options This product has multiple variants. The options may be chosen on the product pageClassic Wooden Stand Hammock Sets, Heavy Duty Hammock Sets

$1,061.68 Select options This product has multiple variants. The options may be chosen on the product pageHammock Sets with Canopy, Heavy Duty Hammock Sets

$286.31 Select options This product has multiple variants. The options may be chosen on the product pageHeavy Duty Hammock Sets, Wooden Arc Stand Hammock Sets

$878.66 Select options This product has multiple variants. The options may be chosen on the product pageCamping Hammock Sets with Bug Net, Complete Camping Hammock Systems

Price range: $82.73 through $97.96 Select options This product has multiple variants. The options may be chosen on the product pageComplete Camping Hammock Systems, Hanging Egg Chair Sets

$266.73 Select options This product has multiple variants. The options may be chosen on the product page

10. Are Fully Waterproof Hammocks Worth It?

While most hammock systems separate water protection duties between a waterproof tarp and a water-resistant hammock body, some manufacturers offer fully waterproof hammock bodies. Let’s examine whether this integrated approach delivers on its promises.

Potential Advantages

Simplified Setup: Fully waterproof hammocks eliminate the need for separate tarp setup in light rain conditions, potentially saving time during deployment.

Integrated Protection: With waterproofing built into the hammock itself, there’s one less component to pack, carry, and potentially lose.

Peace of Mind: For beginners especially, the all-in-one approach can reduce anxiety about proper tarp positioning and coverage.

Significant Limitations

Condensation Issues: The most critical drawback is condensation management. Waterproof materials that prevent rain from entering also trap moisture from your body inside, creating a clammy, uncomfortable sleeping environment.

Comfort Reduction: Truly waterproof materials typically feel less comfortable against the skin than the breathable fabrics used in standard hammocks.

Weight Penalties: Adding waterproof layers to the hammock body increases weight compared to ultralight hammock + separate tarp systems.

Cost Increase: Quality fully waterproof hammocks generally cost more than comparable separate component systems.

When Might They Make Sense?

Fully waterproof hammocks can be appropriate for specific scenarios:

– Very short trips with minimal chance of extended rain

– Emergency shelter situations where simplicity trumps comfort

– Environments where setup space is extremely limited

– As backup systems when weight and space aren’t primary concerns

For most hammock campers, however, the traditional approach of using a water-resistant hammock body combined with a properly sized waterproof tarp remains superior. This system provides better moisture management, greater comfort, often lighter total weight, and more flexibility to adapt to changing conditions.

11. Conclusion

Effective waterproofing transforms hammock camping from a fair-weather activity into a year-round possibility, allowing you to enjoy the outdoors regardless of conditions. Throughout this guide, we’ve explored how proper material selection forms the foundation of a reliable water protection strategy.

The ideal approach combines:

– A properly sized waterproof tarp made from appropriate materials for your conditions and budget

– A water-resistant hammock body that balances moisture management with comfort

– Strategic supplementary techniques to address common water entry points

– Proper maintenance routines to preserve waterproof properties

When selecting materials, remember that each option presents a unique balance of properties. Silnylon offers excellent strength-to-weight ratio but requires adjustment when wet. Silpoly maintains tension in rain but with slightly lower tear strength. DCF provides unmatched lightweight performance at premium prices. PU-coated options deliver adequate protection at budget-friendly prices but with reduced longevity.

Understanding the differences between cotton and polyester hammocks also informs your waterproofing strategy, as base materials significantly impact how additional treatments perform.

By approaching hammock waterproofing as an integrated system rather than focusing solely on materials, you create a reliable shelter that performs in diverse conditions. With proper selection, setup, and maintenance, your waterproof hammock system will provide years of comfortable outdoor experiences, regardless of what the weather brings.

Remember that the most effective waterproofing system is one that matches your specific needs, priorities, and camping style—allowing you to focus less on staying dry and more on enjoying the natural world around you.